Dedicated Return Line Systems That Keep Your Water Hot and Ready

By Brian on July 2, 2025

Why Instant Hot Water Matters More Than Ever

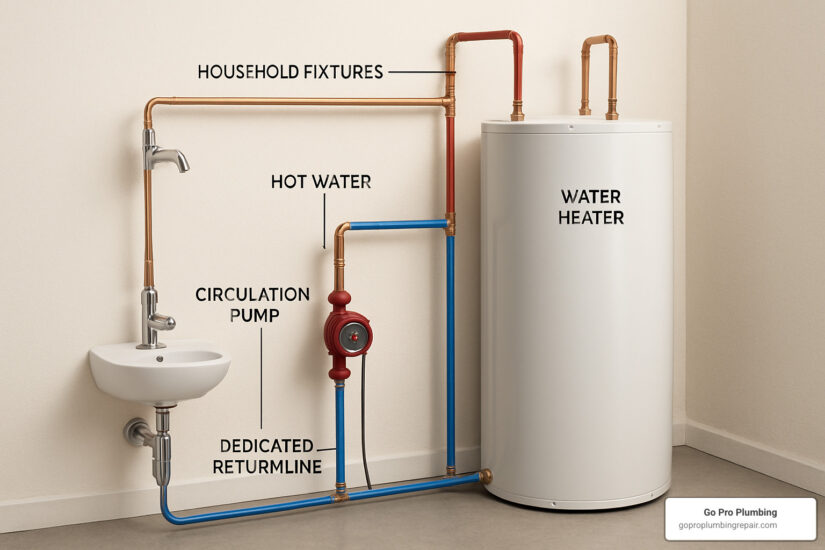

A hot water recirculating system with dedicated return line is a closed-loop plumbing setup that keeps hot water constantly circulating between your water heater and fixtures, delivering instant hot water at every tap without waste.

Key Features of Dedicated Return Line Systems:

- Dedicated return pipe runs from furthest fixture back to water heater

- Circulation pump maintains continuous water flow in the loop

- No cold water contamination – unlike crossover valve systems

- Energy-efficient operation with smart controls and timers

- Water savings of up to 12,000 gallons per year per household

Have you ever turned on a hot water faucet only to have to wait forever for the water to get warm? You’re not alone. The average family of four wastes up to 12,000 gallons of water per year just waiting for hot water to arrive at their taps.

The problem gets worse with today’s larger homes and longer pipe runs. It can take 90 seconds or more for hot water to travel from your water heater to distant bathrooms or kitchens.

That’s where dedicated return line systems shine. Unlike retrofit solutions that use your cold water line as a return path, dedicated systems maintain pure hot water throughout the loop. They’re more efficient, more reliable, and deliver truly instant results.

With rising water costs and California’s ongoing conservation efforts, homeowners are looking for solutions that save both time and resources. Modern recirculation pumps draw as little as 5-8 watts – less than a night light – while eliminating the daily frustration of cold morning showers.

Similar topics to hot water recirculating system with dedicated return line:

- hot water recirculating pump

- hot water recirculation system design

- recirculating hot water system diagram

How a Hot Water Recirculating System with Dedicated Return Line Works

Picture a hot water recirculating system with dedicated return line as your home’s personal hot water highway. Unlike the frustrating stop-and-go traffic of traditional plumbing, this system keeps hot water moving in a smooth, continuous loop so it’s always ready when you turn the tap.

Here’s the beautiful simplicity: your water heater sends hot water through the supply pipe to reach every fixture in your home. But instead of letting that water sit and cool down in the pipes, a dedicated return line carries it right back to the heater for a quick warm-up. A circulation pump acts like the engine that keeps everything moving, while a check valve prevents any backwards flow when the pump takes a break.

The real game-changer is pipe insulation wrapped around both supply and return lines. Think of it as a cozy blanket that keeps your hot water warm during its journey. Without proper insulation, you’re basically heating the air in your crawl space instead of your shower water.

This closed-loop design means hot water never stops moving through your plumbing. It’s like having a dedicated express lane for hot water delivery.

Primary Loop Basics: Supply vs. Return

The flow direction in your system follows a simple but clever path. Hot water leaves your heater through the main supply pipe, then splits off at branch tees to serve individual fixtures like your kitchen sink, bathroom vanities, and shower heads.

Meanwhile, the return line runs a parallel route back to your water heater. This creates a continuous circuit where water that’s cooled down slightly gets pulled back for reheating. The result? Every fixture stays connected to consistently hot water without the usual wait time.

Differences from Non-Dedicated (Crossover) Systems

This is where a hot water recirculating system with dedicated return line really shows its superiority over cheaper alternatives. Some systems try to cut corners by using a retrofit valve under your furthest sink, essentially turning your cold water line into a part-time return path.

The problem with this shortcut becomes obvious pretty quickly. Cold-line warming means your “cold” water faucet starts delivering lukewarm water – not exactly refreshing when you want a cold drink or need to rinse vegetables.

Your plumbing layout also matters here. Crossover systems work within existing pipe runs, but they’re fighting against physics. Cold water lines weren’t designed to handle continuous circulation, so you get inconsistent temperatures and reduced efficiency.

With a true dedicated return system, your cold water stays cold and your hot water arrives instantly. No compromises, no lukewarm surprises – just reliable performance that works the way it should from day one.

Key Components & Sizing Guide

Getting the right components for your hot water recirculating system with dedicated return line is like choosing the right ingredients for your favorite recipe – skip the quality parts, and you’ll regret it later. We’ve walked into too many homes where homeowners tried to save a few bucks upfront, only to deal with noisy pumps, lukewarm water, and sky-high energy bills.

Let’s start with pump selection, because this little workhorse makes or breaks your system. Modern variable-speed ECM pumps (that’s electronically commutated motor, in case you’re wondering) are absolute game-changers. These smart pumps draw just 5-8 watts during operation – less power than your phone charger uses. Compare that to older pumps that could gulp down 100+ watts, and you’ll see why we always recommend upgrading.

Pipe sizing follows some tried-and-true rules that work in the real world. Your main supply line should be ¾ inch, while the return line can be ½ inch for most homes. Here’s a pro tip from our years in Northern California crawlspaces: if your budget allows, go with ¾ inch for both lines. Yes, it costs a bit more upfront, but the faster circulation and quicker response times make it worth every penny.

Now for the age-old debate: PEX vs. copper. Both materials work great for dedicated return lines, but each has its sweet spot:

| Feature | Copper | PEX-A |

|---|---|---|

| Heat resistance | Excellent | Good (rated for constant hot water) |

| Installation | Requires sweating/soldering | Crimping tool needed |

| Flexibility | Rigid, needs fittings | Flexible, fewer connections |

| Cost | Higher material cost | Lower material cost |

| Durability | 50+ year lifespan | 25-50 year lifespan |

| Corrosion | Can develop pinhole leaks | Resistant to corrosion |

Copper feels traditional and handles heat like a champ, but PEX wins on flexibility and cost. In our experience, PEX-A works beautifully for return lines – it bends around obstacles without fittings, speeds up installation, and costs less than copper.

Don’t forget the supporting cast of components. You’ll need an expansion tank (required by code when you add check valves), an aquastat for temperature control, and quality pipe insulation throughout the entire loop. These aren’t optional extras – they’re essential for a system that works properly and efficiently.

Choosing the Right Pump for a Dedicated Return Line

The circulation pump is truly the heart of your hot water recirculating system with dedicated return line. Get this choice wrong, and you’ll hear about it every morning when that thing kicks on like a freight train.

Wet-rotor pumps are your best friend here. Unlike their dry-rotor cousins, these pumps run whisper-quiet and need zero maintenance. The water flowing through them provides both cooling and lubrication – pretty clever engineering, if you ask us.

Understanding high-head vs. low-head requirements sounds technical, but it’s really about matching the pump to your home’s plumbing. Got a long pipe run with lots of twists and turns? That creates more resistance (higher head pressure). Modern smart ECM pumps actually figure this out automatically and adjust their speed accordingly. It’s like having a pump that thinks for itself.

Noise ratings matter more than most people realize. We’ve replaced perfectly functional pumps simply because they sounded like a washing machine on spin cycle. Quality pumps operate so quietly you’ll forget they’re running. Your family will thank you for spending the extra money on a quiet model.

Duty cycle affects how long your pump will last. Running continuously might seem convenient, but intermittent operation (only when you actually need hot water) reduces wear and saves energy. The key is pairing intermittent operation with smart controls so you don’t sacrifice convenience.

Smart Control Options for a Hot Water Recirculating System with Dedicated Return Line

This is where your hot water recirculating system with dedicated return line gets really exciting. Modern controls can turn a basic circulation system into something that feels almost magical.

Timer controls work beautifully if your family keeps predictable schedules. Program the pump to run during your morning rush and evening routines, then let it rest during the day when nobody’s home. A simple digital timer costs under $50 and can cut your operating costs in half.

Temperature sensors (also called aquastats) add real intelligence to the system. These clever little devices clip onto your return pipe and only activate the pump when water temperature drops below your set point – usually around 95-105°F. No more wasted energy heating water that’s already hot.

Motion detectors bring us into the future. Walk into your bathroom, and the system senses your presence and starts delivering hot water before you even reach the shower. Some Bluetooth-enabled systems can detect you from up to 300 feet away – pretty impressive technology.

Push-button activation gives you complete control. Install wireless buttons near your fixtures, and you get hot water exactly when you want it. Some of our customers love this approach because they never waste energy on timers or sensors.

Voice assistant integration makes your recirculation system part of your smart home. “Hey Google, start the hot water” becomes part of your morning routine, activating the pump while you’re still getting out of bed.

The smartest installations combine multiple controls – timers for daily routines, motion sensors for convenience, and manual override buttons for those times when you just want hot water right now.

Installation Roadmap & Best Practices

Installing a hot water recirculating system with dedicated return line requires careful planning and attention to detail. We’ve completed hundreds of these installations across Northern California, and proper preparation makes all the difference.

Planning the run starts with mapping your hot water lines. In basement or crawlspace installations, route the return line to minimize heat loss and ensure proper support. The return line should connect at the water heater’s drain valve location or a dedicated tapping.

Common mistakes we see include inadequate pipe support, missing insulation, and improper pump placement. Take time to strap pipes every 4-6 feet and insulate the entire loop – heat loss defeats the system’s purpose.

Local code compliance varies by jurisdiction. Most areas require permits for new plumbing work, expansion tanks when check valves are installed, and proper electrical connections for pump power.

Step-by-Step Overview

1. Isolate the water heater – Turn off power/gas and water supply. Drain enough water to work safely on connections.

2. Route the return line – Run piping from the furthest fixture back to the water heater. Use proper hangers and maintain consistent slope toward the heater.

3. Install check valve – Mount horizontally on the return line to prevent unwanted thermosiphon flow when the pump is off.

4. Mount the pump – Install on the return line near the water heater. Vertical mounting prevents air binding in wet-rotor pumps.

5. Wire controls – Connect pump power and any control devices according to manufacturer instructions. Most pumps require standard 120V power.

6. Test and balance – Fill the system, purge air, and verify proper circulation. Adjust pump speed if variable-speed controls are available.

Avoiding Heat & Energy Losses

Proper insulation makes the difference between an efficient system and an energy waster. We insulate every inch of both supply and return lines with closed-cell foam insulation rated for the operating temperature.

Intermittent operation saves energy compared to continuous circulation. Smart controls run the pump only when hot water is needed, reducing annual operating costs from $50+ to under $20.

Heat traps on your water heater prevent unwanted convection losses. However, ensure your circulation pump can overcome the counter-pressure these devices create. Scientific research on heat-trap benefits shows significant standby energy savings when properly installed.

Pipe routing affects heat loss. Avoid running hot water lines through unconditioned spaces when possible. When unavoidable, use extra insulation and consider heat trace cable in extreme climates.

Performance, Savings & Payback

When homeowners ask us about the real-world benefits of a hot water recirculating system with dedicated return line, we share the numbers from our actual installations. After hundreds of systems installed across Northern California, the results speak for themselves.

The water savings alone make these systems worthwhile. A typical family of four saves around 12,000 gallons annually just by eliminating the wait for hot water. At Sacramento’s current water rates, that translates to $150-200 back in your pocket each year. That’s money you’re literally watching go down the drain every morning.

Energy consumption stays surprisingly low with modern pumps. The latest ECM models draw just 5-8.5 watts during operation – less than your phone charger. When you run the system intermittently with smart controls, annual electricity costs stay under $20. Even continuous operation rarely exceeds $40-60 per year.

We typically see return on investment within 3-5 years when you factor in water savings, convenience value, and the boost to your home’s value. High-usage households often see payback even faster. One client with teenage daughters told us the system paid for itself in water savings alone within two years.

Maintenance is refreshingly simple. Quality wet-rotor pumps from manufacturers like Grundfos and Taco run 10-15 years with virtually no attention. Your annual “maintenance” involves checking that the pump is running and making sure insulation stays intact. Most homeowners never call us for service between installations.

Real-World Case Studies

We love sharing success stories from actual installations because every home is different. Here are three projects that show how hot water recirculating systems with dedicated return lines perform in the real world.

Our Rancho Cordova new construction project in 2023 involved a sprawling 3,200 square foot home with a central manifold design. The homeowners were frustrated during their first winter – it took nearly two minutes for hot water to reach their master bathroom 75 feet from the water heater.

We installed ¾” supply and return lines with smart controls that activate via motion sensors and smartphone app. The system knows when someone enters the bathroom and delivers hot water before they reach the shower. The results exceeded expectations: instant hot water at all fixtures and 15,000 gallons in annual water savings.

A 1960s ranch retrofit in Sacramento presented different challenges. The homeowners were remodeling their bathroom and wanted to add recirculation without tearing up the entire house. We used flexible PEX-A piping to snake the return line through existing wall cavities, minimizing damage to finished surfaces.

Simple timer controls run the pump during morning and evening hours when hot water demand peaks. The two-minute wait times are gone, and their water heating bills dropped by 12%. Sometimes the simplest solutions work best.

Our smart on-demand system installation showcases the latest technology. This two-story Northern California home features voice-activated controls that respond to Alexa commands, plus wireless push buttons near each fixture. An advanced aquastat prevents the pump from running when water is already hot.

The homeowners love the control this gives them. “Alexa, start the hot water” becomes part of their morning routine. The system achieved a 95% reduction in pump run time compared to continuous operation, keeping annual operating costs under $15.

Each installation teaches us something new, but the results remain consistent: immediate convenience, substantial water savings, and happy homeowners who wonder why they waited so long to install their hot water recirculating system with dedicated return line.

Frequently Asked Questions about Hot Water Recirculating Systems with Dedicated Return Lines

After installing hundreds of these systems throughout Northern California, we get the same questions from homeowners time and again. Let’s tackle the big three that come up on almost every job.

What pipe size should my return line be?

Here’s the honest answer: ½” return line diameter handles most residential jobs just fine, especially for runs under 50 feet. It’s what many contractors use because it keeps costs reasonable and gets the job done.

But here’s what we’ve learned from years of installations – ¾” return lines perform noticeably better when you can swing the extra cost. The larger diameter reduces flow resistance, which means faster response times when you turn on that faucet. Your pump doesn’t have to work as hard either, which can extend its life.

For the supply line, stick with ¾” throughout the main trunk with ½” branches feeding individual fixtures. This sizing gives you plenty of flow without breaking the bank on materials.

If you’re building new or doing a major remodel, go with the ¾” return. If you’re retrofitting an existing home and every dollar counts, ½” will still deliver the hot water convenience you’re looking for.

Should I choose copper or PEX for the return line?

This question sparks more debate than you’d expect! Both materials work great for hot water recirculating systems with dedicated return lines, but they each have their sweet spots.

PEX-A wins on most residential jobs because it’s simply easier to work with. It bends around corners without fittings, slides through tight spaces, and costs significantly less than copper. Modern PEX handles constant hot water circulation without any issues – we’ve never had a callback for PEX failure in a recirculation system.

Copper brings that premium feel and will likely outlast PEX by decades. It transfers heat efficiently and looks professional in exposed installations. But it requires skilled installation, costs more upfront, and can develop pinhole leaks in areas with aggressive water chemistry.

For most homeowners, we recommend PEX-A. It’s proven reliable, budget-friendly, and perfect for the hidden return line runs where appearance doesn’t matter. Save the copper for visible supply lines if you want that classic look.

How often does the circulation pump need service?

Here’s some good news – quality circulation pumps are basically “install and forget” devices. The wet-rotor designs we use run for years without any attention beyond a quick visual check.

Annual inspection takes about two minutes. Just look for leaks around the pump connections and listen for unusual noises. A healthy pump runs whisper-quiet – if you hear grinding, rattling, or loud humming, it’s time for a replacement.

Most pumps give us 10-15 years of trouble-free service. When they do fail, replacement usually makes more sense than repair. The good news? Pump technology keeps improving, so your replacement will likely be more efficient than the original.

Flushing the system every 3-5 years helps prevent sediment buildup, especially if you have hard water. This simple maintenance step can extend pump life and maintain optimal performance throughout your home.

The bottom line? These systems are remarkably reliable when installed properly. That’s why we’re confident offering same-day service when you need it – most of our calls are for new installations, not repairs.

Conclusion

Installing a hot water recirculating system with dedicated return line is one of those home improvements that makes you wonder why you waited so long. The daily convenience of instant hot water at every faucet transforms your morning routine, while saving up to 12,000 gallons of water annually. That’s real money back in your pocket and a meaningful contribution to water conservation.

What really sets dedicated return line systems apart is their reliability. Unlike crossover valve systems that warm up your cold water lines, dedicated systems keep hot and cold water completely separate. You get consistently hot water when you want it, refreshingly cold water when you need it, and no compromises in between.

The technology keeps getting better too. Today’s smart ECM pumps run whisper-quiet while using less electricity than a standard light bulb. Add motion sensors or voice controls, and you’ve got a system that feels almost magical – hot water appears exactly when and where you need it.

Here at Go Pro Plumbing, we’ve seen how these systems change people’s lives. From busy families rushing through morning routines to homeowners who simply want their house to work better, the response is always the same: “Why didn’t we do this sooner?”

Our team has installed dedicated return systems throughout Northern California, and we understand the unique challenges of retrofitting older homes while maximizing efficiency in new construction. Same-day service means we can often evaluate your home’s layout and provide a detailed quote on the same visit.

The math works in your favor too. Between water savings, increased home value, and the daily convenience factor, most systems pay for themselves within 3-5 years. After that, it’s pure savings – both in your utility bills and your morning stress levels.

Ready to join the thousands of Northern California homeowners enjoying instant hot water? Contact Go Pro Plumbing for a consultation. We’ll walk through your home’s specific needs and show you exactly how a hot water recirculating system with dedicated return line can work for your family. More info about plumbing services or give us a call – we’re here to make your home more comfortable, efficient, and enjoyable.