CIPP Explained: How Trenchless Pipe Lining Works

By Brian on December 19, 2025

Understanding the Pipe-Within-a-Pipe Solution

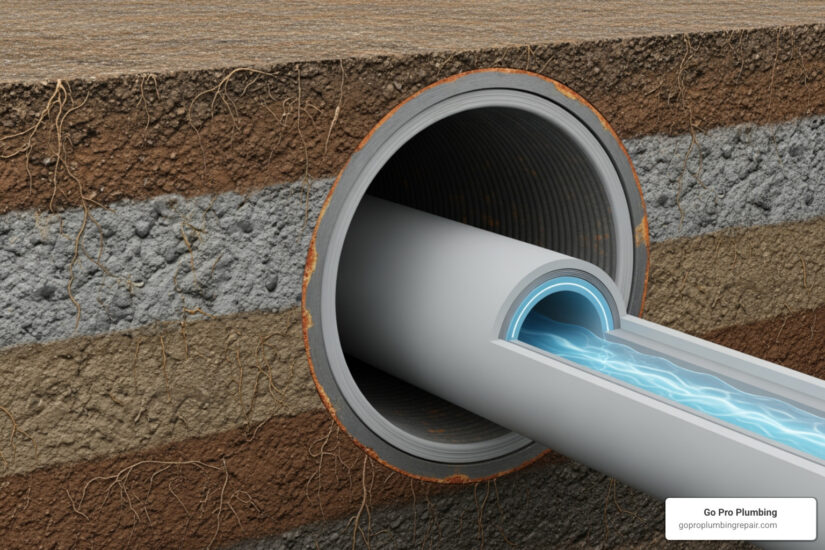

Cured in place pipe (CIPP) is a trenchless rehabilitation method that repairs damaged underground pipes by creating a new, seamless pipe inside the existing one—without digging up your yard or driveway.

Quick Answer: What You Need to Know About CIPP

- What it is: A resin-saturated liner inserted into damaged pipes and cured to form a structural “pipe within a pipe”

- How it works: Felt tube soaked in resin + inserted into pipe + cured with heat = brand new pipe

- Best for: Sewer lines, water pipes, storm drains (4-110 inch diameter)

- Key benefit: No excavation required—access through existing manholes or cleanouts

- Lifespan: 50+ years of service life

- Cost: Often half the price of traditional dig-and-replace methods

If you have slow drains, sewage backups, or wet spots in your yard, your underground pipes might be damaged. Traditionally, this meant tearing up your property, but CIPP technology changed everything.

This trenchless method, used since 1971, now accounts for half of all sewer line rehabilitation in North America. Instead of replacing your pipe system, CIPP creates a new pipe inside the old one, often in just one day. Technicians clean the pipe, insert a resin-saturated liner, inflate it, and cure it with heat. The result is a jointless, corrosion-resistant pipe that lasts 50+ years.

For Northern California property owners, CIPP offers a same-day solution without the mess and property damage of excavation.

Understanding Cured-in-Place Pipe (CIPP) Technology

Now that you understand the basics, let’s dive deeper into what makes Cured in place pipe technology such a game-changer for pipe rehabilitation.

Instead of digging up and replacing a damaged pipe, CIPP creates a brand new, jointless, seamless pipe within the existing one. This “pipe within a pipe” is a full structural replacement, strong enough to stand on its own even if the old host pipe deteriorates completely.

Developed in 1971 by engineer Eric Wood, the concept was simple: insert a flexible, resin-soaked tube into a damaged pipe and harden it in place. The method was commercialized and became widely adopted after its patent entered the public domain in 1994.

By the 1980s, CIPP arrived in the United States, and today it accounts for half of all sewer line rehabilitation and an eighth of potable water pipe repairs in North America. With a typical lifespan of 50 years or more, it’s easy to see why property owners and municipalities have acceptd this technology.

Primary Applications of CIPP

One of the best features of Cured in place pipe technology is its versatility.

- Sewer lines are the most common application. CIPP effectively repairs residential laterals and municipal mains, fixing issues like root intrusion, cracks, and structural damage.

- Potable water pipes can also be repaired using special NSF-certified materials and strict disinfection protocols to safely restore drinking water lines.

- Storm drains, from residential systems to large municipal infrastructure, are another key application where CIPP restores flow and prevents erosion.

- Gas and chemical pipelines also benefit from CIPP’s corrosion-resistant properties.

The technology is effective on pipes from 4 to 110 inches in diameter. It’s also not limited to circular pipes; it can rehabilitate egg-shaped, ovoid, and box culverts. CIPP can be used for spot repairs or to seal lateral connections, not just full-length lining.

How CIPP Solves Common Pipe Problems

Cured in place pipe technology provides a comprehensive solution to many common issues:

- Corrosion: CIPP creates a new, non-corrosive inner surface, stopping deterioration and protecting the pipe from future damage.

- Cracks and Leaks: The liner seals all cracks and gaps, creating a watertight barrier that prevents leaks for decades.

- Root Intrusion: The seamless, jointless CIPP liner eliminates entry points for tree roots, permanently solving this frustrating problem.

- Structural Defects: The CIPP liner is fully structural, capable of bearing loads and withstanding pressures even if the original host pipe deteriorates completely.

- Inflow and Infiltration (I&I): By creating a sealed pipe, CIPP dramatically reduces I&I—when groundwater enters sewer systems. This prevents treatment plant overloads and lowers municipal costs.

- Improved Flow Capacity: CIPP often improves flow because the new liner’s smooth surface allows water to move more efficiently than it did through the rough, corroded original pipe.

The CIPP Installation Process: A Step-by-Step Guide

The change from a damaged pipe to a brand-new one is where Cured in place pipe technology truly comes to life. Our technicians follow a precise, multi-step process to ensure a lasting repair.

Pre-installation Inspection and Preparation

Proper preparation is critical for a successful installation.

- CCTV Inspection: First, a high-definition CCTV camera inspection is performed. This allows us to identify all defects, locate blockages, and take precise measurements for the new liner.

- Pipe Cleaning: Next, the pipe is thoroughly cleaned using high-pressure hydro-jetting. This removes all debris, scale, grease, and roots to ensure the liner adheres properly.

- Bypass Pumping: To ensure your plumbing remains operational, we set up bypass pumping. This diverts wastewater flow around the work area, allowing you to use your facilities without interruption.

CIPP Materials: Liners and Resins

The strength of a Cured in place pipe repair depends on its high-tech materials.

- The Liner: The liner is a flexible felt tube, often made of polyester or fiberglass. It’s strong enough to be structural yet flexible enough to steer bends. A protective polymer coating keeps the liner intact during installation.

- The Resin: The liner is saturated with a thermosetting resin. The type of resin—polyester, epoxy, or vinyl ester—is chosen based on the application. A catalyst in the resin is activated by heat or UV light, causing the flexible liner to harden into a rigid, structural pipe.

Installation and Curing Methods

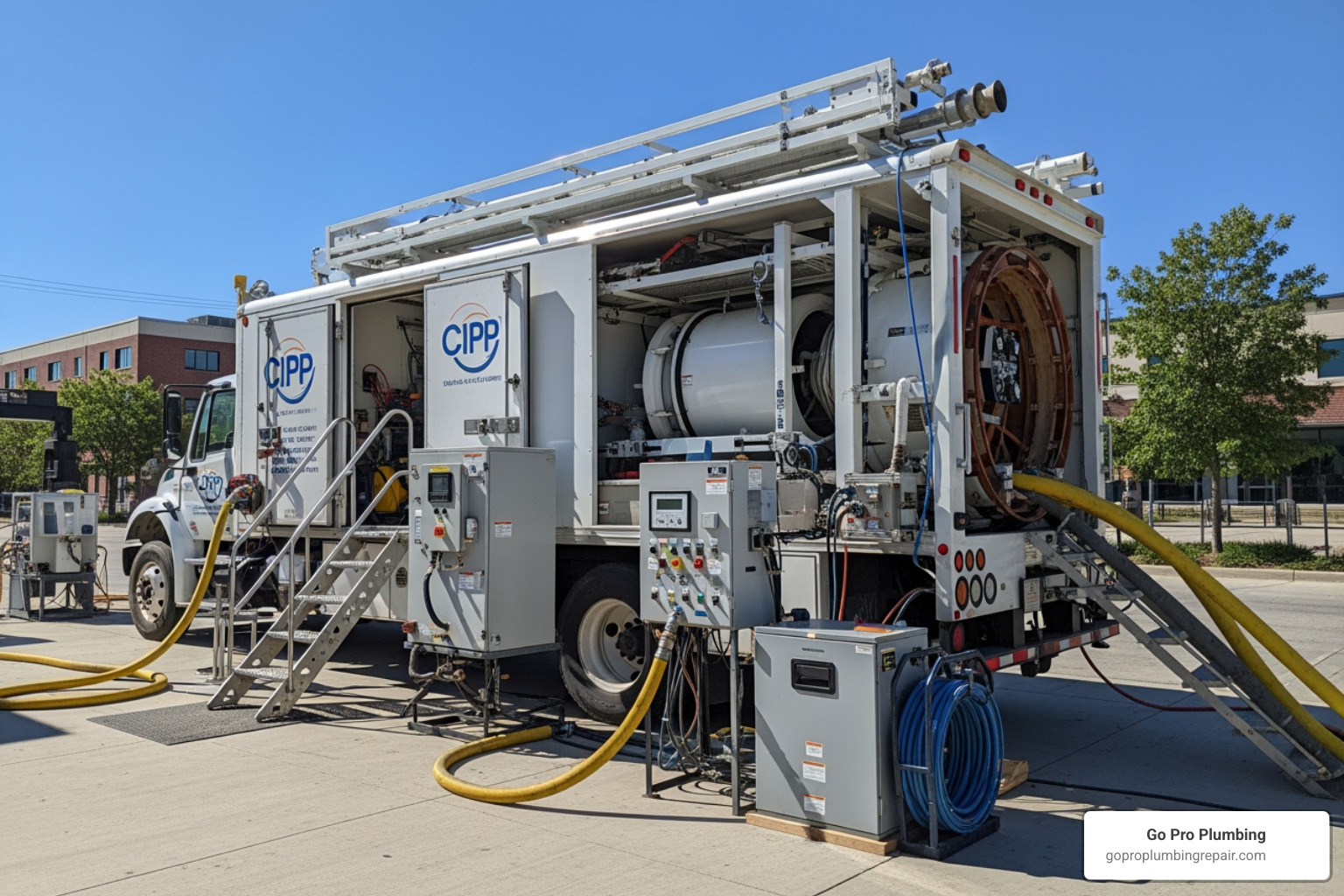

With the pipe prepared, the trenchless installation begins.

- Liner Insertion: The resin-saturated liner is inserted into the host pipe. The inversion method uses air or water pressure to turn the liner inside-out into the pipe, which is the most common technique. For pipes with multiple bends, the pull-in-place method is used, where the liner is pulled into position and then inflated.

- Curing: Next is curing, where the resin hardens. This is done by circulating hot water or steam, or by using a UV light train. The heat or UV light triggers a chemical reaction that solidifies the liner into a new pipe. Curing can take from a few hours to over a day, depending on the method and pipe length.

Post-Installation: Finishing the Job

After the liner has hardened, a few final steps complete the process.

- Cool-Down: After curing with heat, a cool-down period is necessary to prevent stress cracks and ensure long-term durability.

- Reinstate Laterals: The new liner covers branch pipe connections, so we use specialized robotic cutters to reopen them.

- Final Inspection: A final CCTV camera inspection is performed to verify the installation quality and ensure the new pipe is seamless and ready for service.

- Disinfection: For potable water lines, a final disinfection step is performed to ensure the water is safe before the pipe is returned to service.

The entire process is typically completed in a single day, restoring your plumbing system without major disruption.

CIPP vs. Traditional Replacement: Advantages and Disadvantages

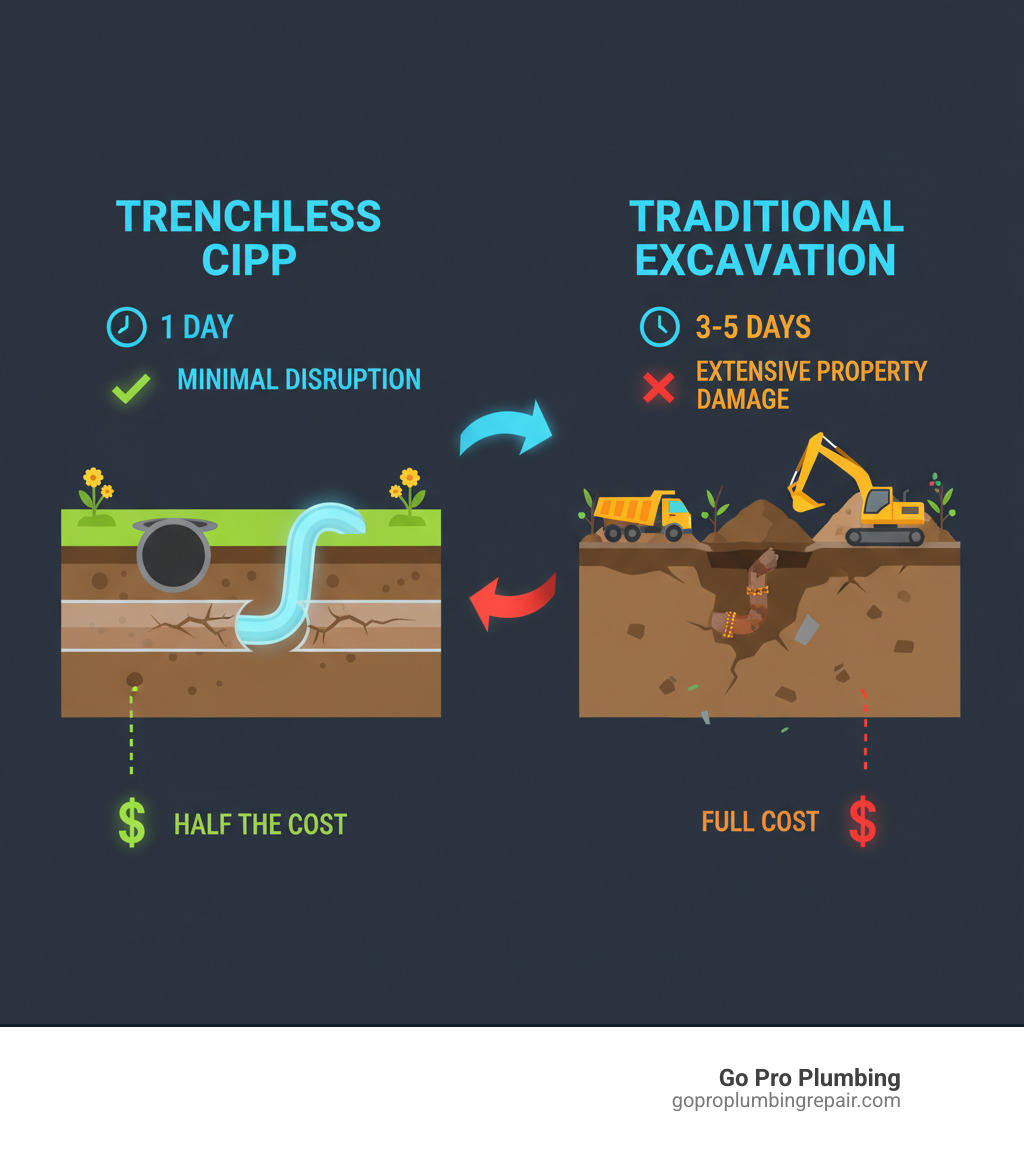

When a sewer line fails, property owners must choose between traditional replacement and modern Cured in place pipe technology. Traditional replacement involves excavating a trench to remove and replace the old pipe. This method is effective but messy, slow, and expensive due to restoration costs.

Cured in place pipe, on the other hand, works from the inside out, avoiding most excavation. We access your pipe through existing manholes or cleanouts, keeping your property intact.

| Feature | CIPP (Cured in place pipe) | Traditional Dig-and-Replace |

|---|---|---|

| Disruption | Minimal to none (access via manholes/cleanouts) | Extensive (trenches, disrupted landscaping/pavement) |

| Cost | Often half the cost of traditional replacement | Generally higher due to excavation and restoration |

| Time | Faster (typically 1 day for many residential jobs) | Slower (3-5 days or more, depending on scope) |

| Longevity | 50+ year design life (some up to 100 years) | Varies, but new pipes are susceptible to same issues as old over time |

| Versatility | Works with various pipe materials, sizes, and bends | Limited by excavation access, usually straight pipe sections |

| Flow Capacity | Often improved due to smooth, jointless interior | New pipe, but potential for future friction points |

| Structural | Creates a structural “pipe within a pipe” | Replaces with new pipe, but soil compaction needed |

| Environmental | Less carbon footprint, minimal waste, eco-friendly | Significant soil disturbance, waste disposal |

The advantages of Cured in place pipe are clear:

- Minimal Disruption: Your landscaping, driveway, and lawn remain intact, avoiding the mess and noise of a major construction project.

- Cost-Effectiveness: CIPP avoids high excavation and restoration costs, often costing about half as much as conventional methods. For homeowners in Sacramento or Rancho Cordova, the savings are significant.

- Time Savings: Most residential CIPP jobs are done in a single day, compared to 3-5 days or more for traditional replacement.

- Versatility & Durability: CIPP is highly versatile, working on nearly any pipe material and navigating bends. The durable, seamless liner has a 50+ year design life and resists corrosion and root intrusion.

Limitations and Considerations for Cured in place pipe

However, CIPP has some limitations to consider before committing to a repair.

- Bypass Service: A temporary bypass is required to divert flow while the pipe is out of service during the work.

- Pre-existing Obstructions: Severe blockages or completely collapsed pipe sections must be addressed before lining can occur.

- Cost: While usually more cost-effective, CIPP is not always the cheapest option for every unique scenario.

- Future Cleaning: After installation, cleaning must be done with hydrojetting (high-pressure water), as mechanical snakes can damage the liner. The good news is that the smooth surface means cleaning is needed far less often.

At Go Pro Plumbing, we’ll walk you through these considerations to help you choose the best repair method for your property and budget. For most Northern California homeowners, Cured in place pipe delivers outstanding results with minimal hassle. Want to learn more? Contact us for sewer line replacement services for a thorough assessment.

Safety, Standards, and Quality Control for Cured in place pipe

At Go Pro Plumbing, we don’t just fix pipes—we do it right. For Cured in place pipe installations, safety and quality are the foundation of every project.

Quality Assurance and Quality Control

Quality control is critical for every Cured in place pipe installation. We adhere to industry standards like ASTM F1216 and best practices from organizations like the NASSCO CIPP Technology Overview. This ensures every installation meets strict guidelines for materials, procedures, and testing.

Our technicians are specifically trained in CIPP installation and follow manufacturer specifications precisely. Strict oversight on every job ensures a high-quality result designed to last 50 years. Post-installation, we may test material samples to verify physical properties like flexural strength meet design specifications, using tests like ASTM D790 to guarantee a great installation.

Environmental and Health Considerations

While CIPP is less invasive, the resins used contain chemicals that require careful handling, a responsibility we take seriously. We believe in being transparent about these risks.

Resins can contain chemicals like styrene, which may be released as vapors during curing. Our technicians are most at risk, so we follow strict safety protocols based on CDC guidance on CIPP safety. This includes personal protective equipment (PPE), proper ventilation, and continuous training to minimize exposure.

Public risk is low, but professional installation is key to preventing rare issues like plumbing blowback or emissions. We manage all processes carefully to ensure safety and handle all chemical waste according to regulations, protecting your property and the Northern California environment.

The bottom line: CIPP is safe and effective when performed by trained, certified professionals who follow strict procedures. When you choose Go Pro Plumbing, you’re choosing a team that takes these responsibilities seriously.

Frequently Asked Questions about CIPP Lining

We talk to homeowners and business owners across Northern California every day about Cured in place pipe technology. Here are answers to the most common questions we hear at Go Pro Plumbing.

How long does a CIPP liner last?

A CIPP liner is a long-term investment, engineered for a minimum 50-year design life, with some lasting up to 100 years. This longevity is due to the seamless, jointless material that resists corrosion, cracks, and root intrusion, unlike traditional pipe materials. It’s a true “fix it and forget it” solution.

Is CIPP safe for drinking water pipes?

Yes, CIPP is safe for drinking water pipes when using special NSF-certified materials. These materials are different from those used for sewer lines and are rigorously tested to prevent leaching and meet strict health standards.

After installation, a mandatory post-installation flushing and testing process ensures the water is safe before the line is returned to service. We prioritize your family’s health.

Can any pipe be repaired with CIPP?

Almost, but not all. CIPP is highly versatile, working on most pipe materials (cast iron, clay, PVC, etc.) and sizes from 4 to 110 inches in diameter.

However, CIPP is not suitable for severely collapsed pipes, as the liner needs the host pipe to form against. The original pipe must have some remaining structure. Pipes with extreme damage or multiple sharp turns might also need alternative approaches.

That’s why we always start with a thorough CCTV camera inspection. If you’re dealing with pipe issues in Northern California, give us a call. We’ll provide an honest assessment and recommend the right solution for your specific situation.

Conclusion: Is CIPP the Right Choice for Your Pipes?

For most Northern California property owners with damaged pipes, Cured in place pipe is the ideal solution. It avoids property damage, is often half the cost of traditional replacement, and provides a new pipe with a 50+ year lifespan, usually in just one day.

CIPP is a smart, long-term investment. It creates a seamless, corrosion-resistant, and root-proof pipe that solves problems like leaks, root intrusion, and structural weakness at their core, protecting your property for decades.

Of course, every situation is unique, which is why we always start with a thorough CCTV inspection. While CIPP is usually the best option, we provide an honest assessment and recommend the right solution for your specific needs, even if it’s an alternative method.

At Go Pro Plumbing, we’ve seen how Cured in place pipe technology transforms what used to be a homeowner’s nightmare into a straightforward, stress-free repair. Our commitment to outstanding customer service means we’ll guide you through every step and get your plumbing system back to peak performance with minimal disruption.

If you’re tired of dealing with recurring pipe issues and want a modern solution that delivers real value, it’s time to explore the trenchless advantage.

Contact us for sewer line replacement services and let’s discuss how CIPP can solve your pipe problems efficiently, affordably, and with the same-day service that’s made us Northern California’s trusted plumbing partner.