The Plastic Predicament: Repairing Your Gas Line with Confidence

By Brian on September 1, 2025

Why Plastic Gas Line Repair Requires Immediate Professional Attention

Plastic gas line repair is a serious safety issue requiring immediate professional help. Unlike water line repairs, gas line damage poses life-threatening risks like fire, explosion, and toxic gas exposure.

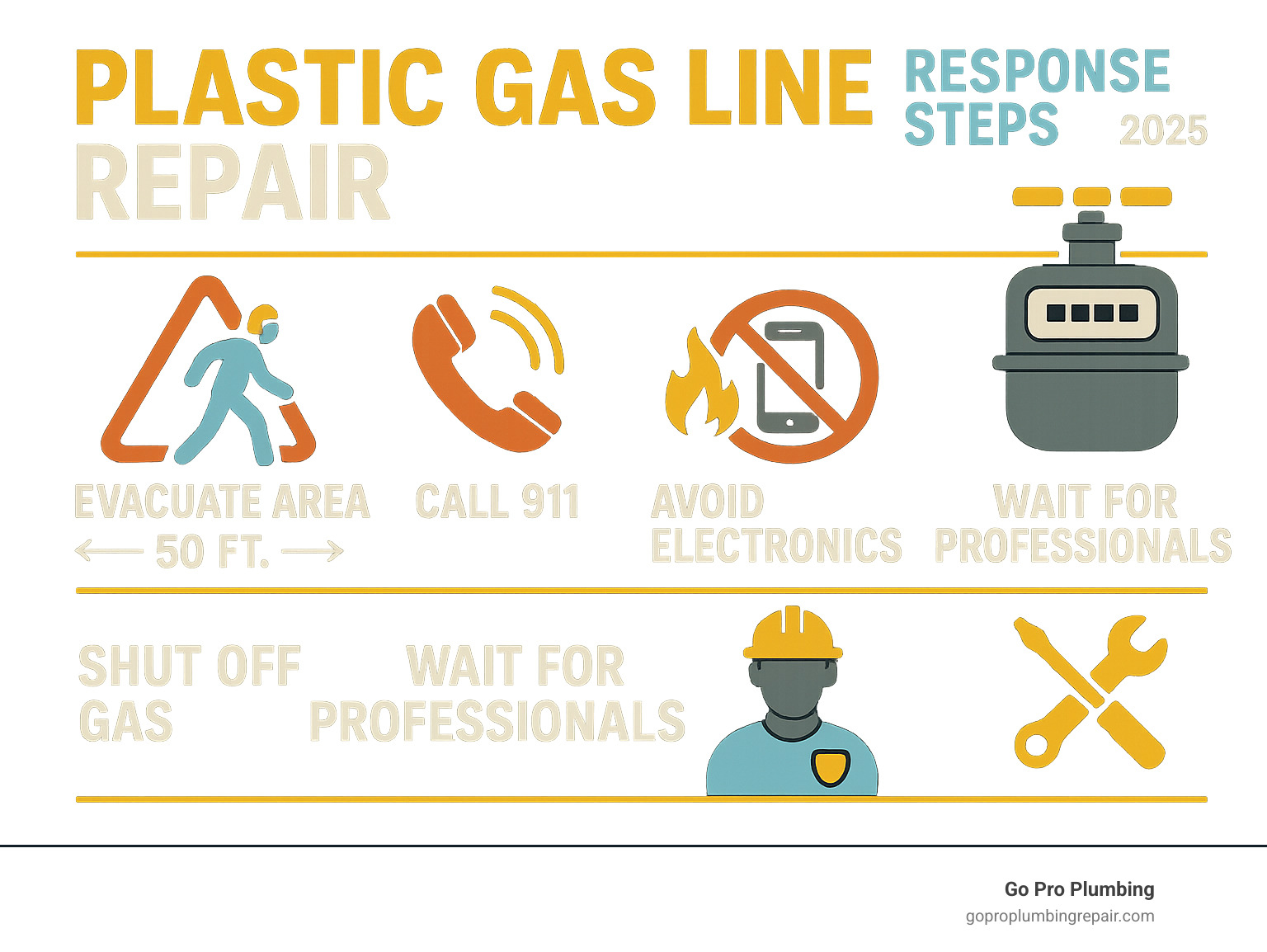

If you have a damaged plastic gas line, follow these critical steps:

- Evacuate the area immediately – Move everyone at least 50 feet away

- Call 911 – Report the gas leak to emergency services

- Shut off gas at the meter – Only if you can do so safely

- Avoid all ignition sources – No smoking, electrical switches, or cell phones

- Contact a certified gas plumber – Never attempt DIY repairs

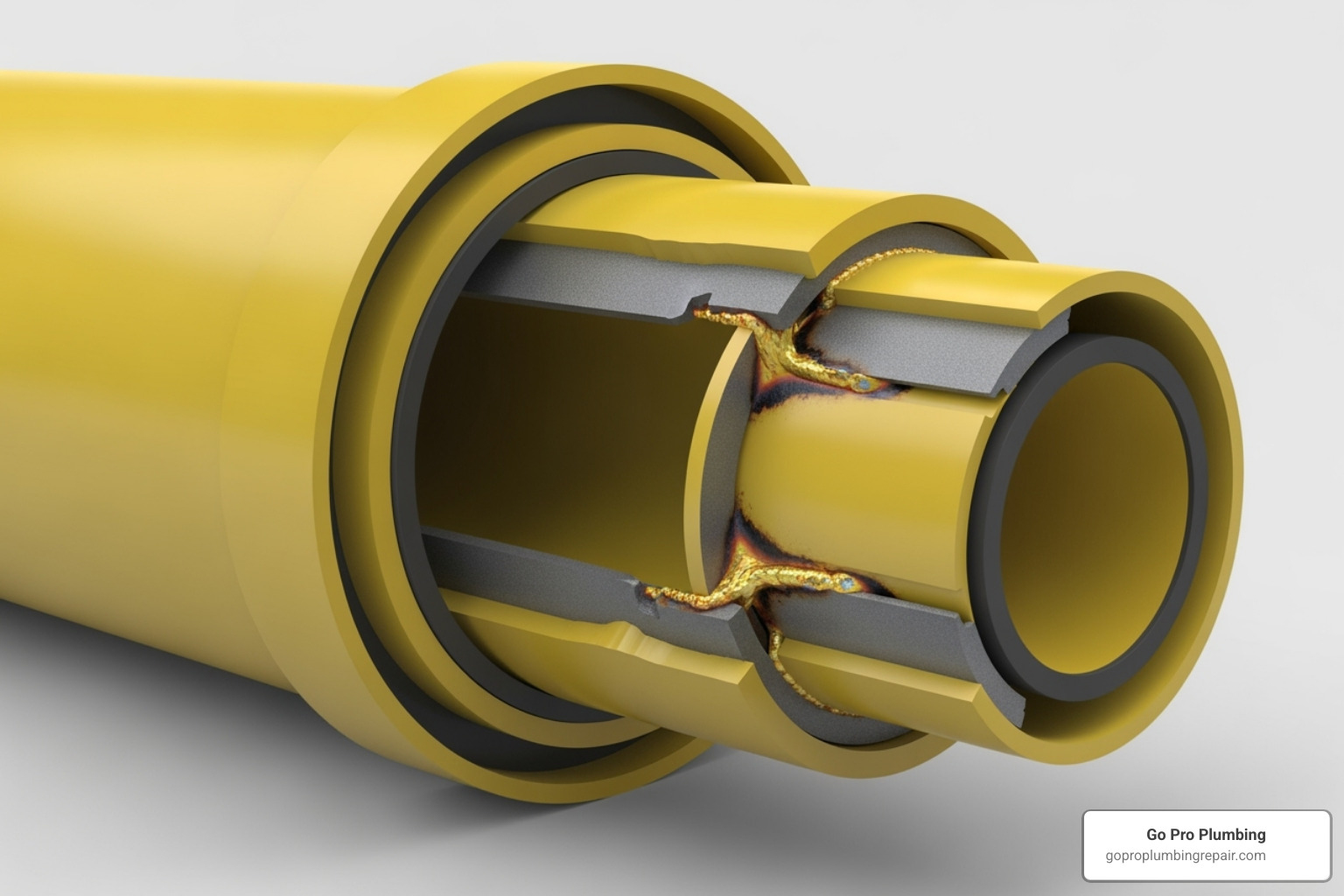

Polyethylene (PE) pipe is the most common material for underground natural gas lines in North America. These yellow plastic pipes can be punctured by ground impact, joint failures from shifting soil, or landscaping activities.

As one homeowner found the hard way: “We learned that our gas line was buried only 6 inches below ground when we punctured it while turning soil for some flowers.”

The good news is that professional repair methods using approved mechanical couplings and compression fittings can safely restore your gas line. But remember: gas line repair is never a DIY project. Even small punctures require specialized tools, approved materials, and professional testing to ensure your family’s safety.

Plastic gas line repair word roundup:

The Unmistakable Dangers: Why Gas Line Repair is Not a DIY Project

Let’s be clear: plastic gas line repair is not a DIY project. Natural gas is a highly flammable substance that can turn your home into a disaster zone. It doesn’t care if you’re handy with a wrench; a mistake can be catastrophic.

Natural gas is designed to burn, which is great when contained in an appliance. But a leak from a damaged line creates serious explosion hazards that can level a house and endanger entire neighborhoods.

Unlike a leaky faucet, which might cause water damage, a damaged gas line presents a much higher risk. Gas vs. water lines are fundamentally different; gas lines are pressurized and carry a substance that can kill through explosion, fire, or asphyxiation.

That’s why stricter codes govern every aspect of gas line work. We’re not talking about the same materials you’d use for water pipes. Incorrect materials like PVC glue, electrical tape, or a random clamp from your garage can fail catastrophically. When they do, you’re not just looking at property damage—you could face serious legal liability for any resulting injuries or deaths.

Professional repair is about more than just tools. It requires understanding gas pressure, using approved materials, and proper testing. A certified professional knows even a tiny leak can fill a space with explosive gas, creating a bomb waiting for a spark.

If you’re dealing with a gas line emergency right now, don’t wait – contact our Emergency Gas Line Service immediately. And remember, California residents can find additional safety information at California Proposition 65 Warning Information.

The bottom line? Your family’s safety isn’t worth the risk of a DIY disaster. Leave gas line repairs to the professionals who have the training, tools, and insurance to do the job safely.

Identifying the Damage and Preparing for Repair

Plastic gas line repair requires detective work to identify the problem before a professional can fix it. Since most plastic gas lines are underground, this usually involves careful digging.

Fortunately, gas lines are easy to identify. Polyethylene (PE) gas pipes are bright yellow, the universal color code that distinguishes them from water, sewer, or electrical lines.

These yellow pipes are also covered in helpful markings that run along their length, acting as the pipe’s ID card. They tell you the manufacturer and product name, confirm the pipe material (usually marked “PE”), and most importantly, reveal the pipe size.

Gas pipes use sizing systems like Iron Pipe Size (IPS) or Outer Diameter (OD), with markings like “1 in. IPS DR 11.” This is critical because repair fittings must match the pipe size exactly—there’s no “close enough” with gas lines. The markings also show the pressure rating and standard compliance, proving the pipe meets safety requirements.

After careful excavation, professionals assess the damage. Punctures are the most common issue, often caused by digging or driving stakes. The homeowner who hit their line while planting flowers is a classic example. Punctures can range from tiny holes to large tears.

Cracks develop more slowly, usually from ground shifting, stress, or age. Joint failures occur where pipe sections connect, often because of improper installation, ground movement, or wear and tear.

Once damage is spotted, the gas supply is shut off immediately and the area is ventilated. The excavation around the damaged section requires extreme care to avoid causing more damage.

We can’t say this enough: this identification and preparation stage requires professional expertise. Trying to dig around a gas line without proper utility location services is like playing Russian roulette with your property. If you suspect damage, reach out for our expert Gas Pipe Leak Repair services.

Approved Repair Methods and Materials

For plastic gas line repair, you can’t use just any tool or material. It’s like surgery—it requires the right tools, materials, and expertise. A wrong move can have deadly consequences.

There are only two approved methods for repairing damaged polyethylene gas lines, both requiring professional expertise. The first is mechanical couplings—specialized fittings that create an airtight seal using compression. These aren’t average hardware store connectors; they are precision-engineered for gas applications, like the HOME-FLEX 1 in. IPS DR 11 Underground Yellow Poly Gas Pipe Coupler, which is “the only underground gas compression fitting on the market.” This highlights how specialized this work is.

The second approved method is heat fusion. Professionals use specialized equipment to melt the pipe and fitting, pressing them together to create a joint that’s stronger than the original pipe. This is not a DIY task.

Now, let’s cover what’s absolutely prohibited for gas line repairs. First, glue or adhesives. Never attempt a DIY repair with glue or bushings on gas lines. These materials aren’t designed for gas pressure or its chemical makeup and will eventually fail, causing a catastrophic leak.

Tape is another no-go. Electrical, plumbing, or self-amalgamating tape cannot handle the pressure and will break down over time.

Finally, unrated clamps are incredibly dangerous. Standard clamps lack the specialized seals and durability needed for gas applications and are a ticking time bomb.

Here’s how the two approved methods stack up:

| Feature | Mechanical Couplings | Heat Fusion |

|---|---|---|

| Method | Compression with internal seals | Melting and joining pipe ends |

| Equipment | Hand tools and specialized fittings | Professional fusion machines |

| Installation | Quicker, no power needed | Slower but creates permanent bond |

| Strength | Very reliable when properly installed | As strong as the original pipe |

| Best For | Repairs and service connections | New installations and major repairs |

Both methods require the expertise that comes with proper training and certification. At Go Pro Plumbing, we have the specialized knowledge and equipment to handle these repairs safely. For more information about our comprehensive gas line services, check out our Plumbing Gas Lines page.

Understanding Approved Fittings for a Safe Plastic Gas Line Repair

The fittings used in plastic gas line repair are engineered for the unique challenges of natural gas. These are not generic plumbing parts.

Compression fittings are a common repair type. They create a seal by compressing a gasket around the pipe. They often require stiffener inserts inside the pipe ends to prevent collapse under pressure, which is essential for a proper seal.

Stab fittings are another option where you simply push the pipe into the fitting, and an internal mechanism grabs and seals it. This design simplifies installation by removing guesswork about torque values. You can find more Information on stab-type fittings.

Electrofusion fittings have built-in electrical heating coils that melt the fitting and pipe when current is applied, creating an incredibly strong, seamless joint.

Some newer push-fit technology designed for gas is appearing, though it’s less common for underground installations.

All fittings must meet strict material requirements. They must be corrosion-resistant to withstand moisture and soil, which is why you see brass and specialized polyethylene compounds. The gas-rated seals (O-rings and gaskets) must be made from materials that won’t break down when exposed to natural gas and can handle extreme temperatures, sometimes from -40°F to 250°F.

Using anything less than an approved, gas-rated fitting installed by a certified professional isn’t worth the risk.

When to Hire a Professional for Gas Line Work

To be clear: for any gas line work, especially plastic gas line repair, you must always hire a professional. This is a matter of law, safety, and common sense.

Natural gas systems are complex and highly regulated. Local codes and permits govern everything from pipe type to burial depth. A homeowner attempting a DIY repair will likely violate these codes, creating a dangerous situation and risking significant fines or legal liability.

A qualified professional for gas line repair must be a certified gas plumber. This means they are:

- Licensed: They hold a valid state plumbing license, demonstrating competency and adherence to professional standards.

- Insured: This protects you and the plumber in case of accidents or property damage.

- Certified in Gas Piping: Many jurisdictions require specific certifications for working with gas lines, ensuring the plumber has specialized training in gas system design, installation, and repair.

In Northern California, where Go Pro Plumbing operates, these regulations are strictly enforced. Our plumbers are licensed, insured, and possess the specific certifications required to work on natural gas lines. We understand the local codes and permitting processes in areas like Sacramento, CA, and Rancho Cordova, CA, ensuring every repair is compliant and safe.

The cost of hiring a professional is an investment in safety that pales in comparison to the potential cost of an amateur mistake. A quote for “$800 for a repair,” as noted by one forum user, reflects the specialized skills, tools, and risks involved. For professional and compliant gas line repairs, trust our certified experts. You can find more information on our Certified Gas Plumber Sacramento CA page.

The Professional Plastic Gas Line Repair Process

When you call a certified professional for plastic gas line repair, you get a carefully planned process designed for maximum safety. Here are the steps we follow:

- Safe Excavation and Utility Line Location: Before digging, we call 811 to have all underground utility lines marked. Excavation around the gas line is then performed carefully, often by hand, to avoid further damage.

- Gas Shut-Off and Purging: The gas supply is shut off at the meter. If needed, the line is purged to remove any remaining gas for a safe working environment.

- Clean Pipe Cuts: The damaged section of PE pipe is cut out using specialized plastic pipe cutters to ensure a clean, straight, and burr-free cut, which is essential for a good seal.

- Chamfering and De-burring: The cut ends of the pipe are prepared. Chamfering creates a bevel on the pipe’s edge to help it slide into fittings without damaging seals. De-burring removes any plastic shards that could interfere with the seal or gas flow. Chamfering tools are essential for proper installation.

- Fitting Installation: The approved fitting is installed according to the manufacturer’s exact specifications. This is critical and involves applying precise torque for compression fittings or ensuring correct seating for stab fittings.

- Inspection and Testing (covered in detail next): After the repair, the line is rigorously inspected and pressure tested before gas flow is restored.

This methodical approach ensures your plastic gas line repair is a safe and lasting solution, reflecting the precision we apply to every job, from Gas Line Installation to minor adjustments.

Post-Repair Inspection and Testing

The repair isn’t complete until it’s proven to be leak-free. This post-repair inspection and testing phase is a non-negotiable part of professional plastic gas line repair.

The primary method is pressure testing. The repaired section is isolated, and air or an inert gas is used to pressurize it above its normal operating pressure. A manometer monitors the pressure; it must hold steady for a required period to indicate there are no leaks.

Even after a successful pressure test, we use additional leak detection methods:

- Soap Solution Test: A specialized soap solution is applied to all new joints. Bubbles will form if any gas is escaping.

- Electronic Gas Detectors: These highly sensitive devices can pinpoint the exact location of a leak, detecting gas concentrations far below what a human can smell.

Once the repair passes all tests, the line is reconnected to the gas supply.

Finally, proper backfilling is crucial. The excavated area is refilled, ensuring the pipe is protected. A tracer wire is often buried alongside the pipe to allow for future electronic location, preventing accidental punctures.

This rigorous testing and backfilling process ensures your plastic gas line repair is safe and reliable for years. It’s part of our commitment to your safety and aligns with our comprehensive Gas Line Maintenance practices.

Frequently Asked Questions about Plastic Gas Line Repair

When dealing with a damaged gas line, you have questions. Let’s tackle the most common ones we hear about plastic gas line repair.

Can I use PVC glue or a rubber clamp to patch a small hole in a gas line?

Absolutely not! While it might seem logical, this thinking could be explosive.

The reality is that glues and solvents are not rated for gas pressure or the chemical composition of natural gas. They will break down over time and fail. Similarly, unrated clamps can fail under gas pressure, leading to a catastrophic leak.

Think of it this way: you wouldn’t patch your car’s gas tank with duct tape. The same principle applies here, but with the higher stakes of your home and family’s safety.

Only approved mechanical or fusion fittings are safe for gas line repairs. These are specifically engineered and tested for natural gas applications.

How deep should a plastic gas line be buried?

The burial depth for gas lines varies by local code, but residential lines are typically buried 18 to 24 inches deep.

Here’s a perfect example from one of our customers: “We learned that our gas line was buried only 6 inches below ground when we punctured it while turning soil for some flowers.” This shallow burial made their line vulnerable.

Proper depth protects the line from accidental damage from activities like gardening or installing a fence. When we complete a plastic gas line repair, we ensure the line is reburied at the correct depth according to local codes.

How much does a professional plastic gas line repair cost?

We can’t give a single answer because cost varies significantly based on several key factors.

The extent of damage plays a huge role. A small, easily accessible puncture will cost less than a complex repair under a concrete driveway. Accessibility matters too—less labor is needed if we can easily reach the damaged area.

Location and local labor rates also factor into the equation. Costs in Sacramento might differ from other parts of Northern California.

Remember: a professional repair is an investment in the safety of your home and family. A quote that seems high includes the expertise of a certified gas plumber, specialized materials, careful excavation, and thorough pressure testing.

The real question isn’t “How much does it cost?” but “What’s the cost of not doing it right?” Preventing far costlier accidents—like explosions or fires—is priceless.

At Go Pro Plumbing, we provide transparent, upfront quotes so you know exactly what you’re investing in.

Conclusion

If there’s one takeaway from this guide, it’s that plastic gas line repair is not a DIY project. The stakes are too high when dealing with natural gas, and you should never cut corners.

Throughout this guide, we’ve seen that a gas line repair demands a different level of respect than typical plumbing. A leaky faucet might flood a bathroom, but a botched gas line repair could put your entire family at risk from fire, explosion, or toxic exposure. This is a job that requires professional expertise every single time.

Using approved fittings isn’t just recommended—it’s critical. Specialized mechanical couplings and heat fusion techniques are the only safe way to restore your gas line’s integrity. Quick fixes like glue, tape, or hardware store clamps are not just ineffective; they’re dangerous.

Technical details like understanding your pipe’s size and type, ensuring proper burial depth, and following a meticulous repair process are not just bureaucratic steps. They are what separates a safe repair from a ticking time bomb.

At Go Pro Plumbing, we care about keeping Northern California families safe. Our certified gas plumbers have the tools and training, but they also understand that behind every plastic gas line repair is a family who deserves peace of mind.

Whether you’re in Sacramento, Rancho Cordova, or anywhere else in our Northern California service area, we’re committed to providing same-day service and outstanding customer care. We know that when you find a damaged gas line, waiting isn’t an option.

Don’t gamble with your family’s safety. When it comes to gas line issues, trust the professionals who understand the science and the stakes involved.

Contact us for professional gas line repair services today. We’re here to handle your gas line challenges with the expertise, care, and urgency they deserve.