Fix Your Toilet: Easy Bottom Entry Fill Valve Replacement

By Brian on January 8, 2026

Why Your Bottom Entry Fill Valve Matters

Replace bottom entry fill valve issues quickly to stop water waste and end that annoying running toilet sound. Here’s what you need to know:

Quick Answer: Replacing a Bottom Entry Fill Valve

- Turn off water at the shut-off valve and drain the tank

- Disconnect the supply line and remove the locknut under the tank

- Lift out the old valve and adjust the new valve height

- Install the new valve, reconnect the supply line, and adjust water levels

- Total time: About 10-15 minutes for most DIYers

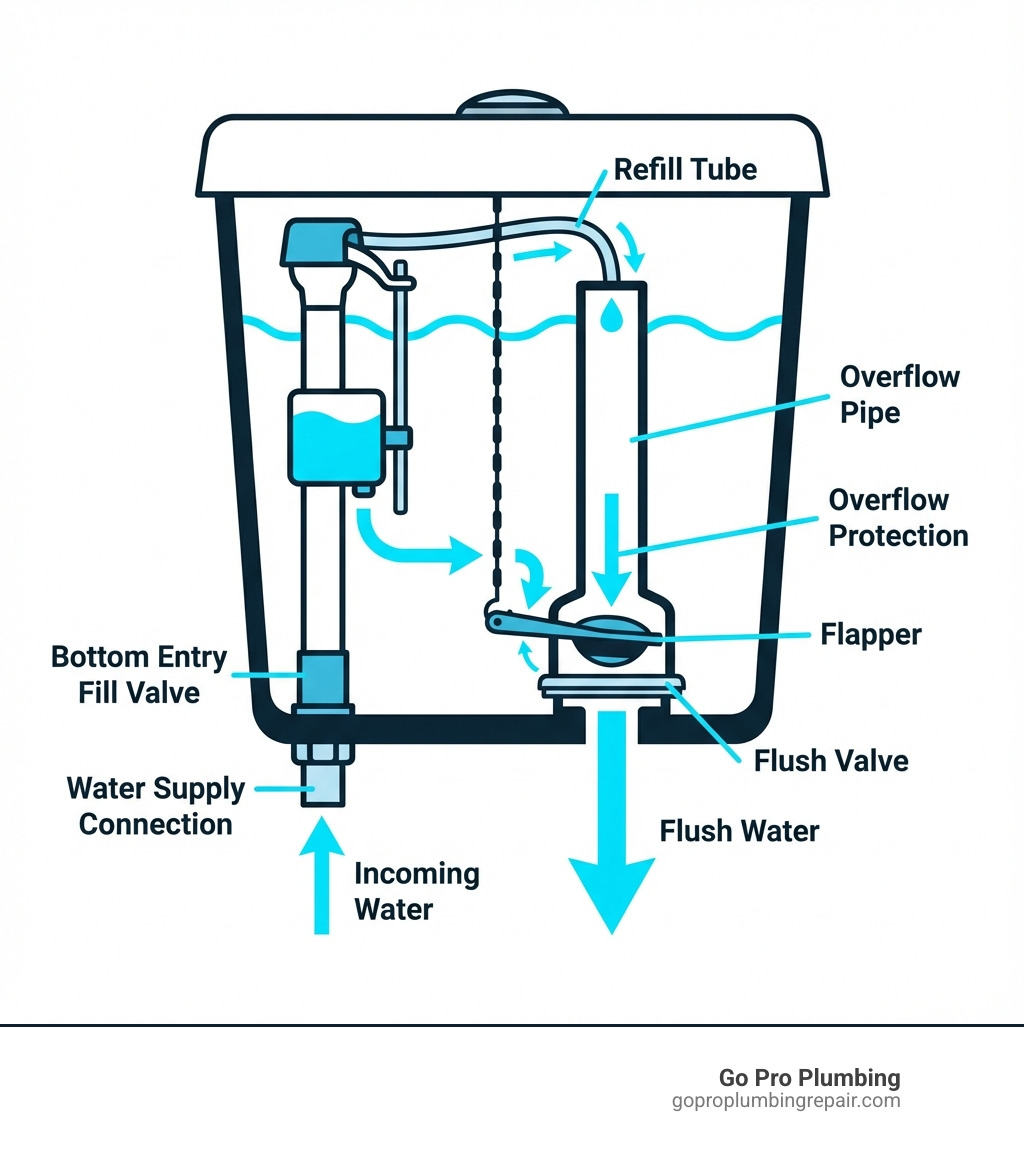

Is your toilet running constantly? Making strange hissing sounds? Refilling painfully slowly? You’re probably dealing with a faulty fill valve. This small but mighty component controls how water enters your toilet tank after each flush.

When it fails, you’re not just dealing with an annoyance—you’re literally watching money flow down the drain. A constantly running toilet can waste thousands of gallons of water each year.

The good news? Replacing a bottom entry fill valve is one of the easiest plumbing repairs you can do yourself. You don’t need special skills or expensive tools. Most homeowners complete this repair in under 30 minutes, and the parts typically cost less than $20.

This guide walks you through every step, from diagnosing the problem to making final adjustments. We’ll also cover what to do when access is tricky and when it makes sense to call in a professional.

Replace bottom entry fill valve definitions:

- change toilet flusher

- replacing toilet flush valve without removing tank

- toilet flush valve replacement

Is Your Fill Valve Faulty? Key Signs and Preparation

Before we grab our tools and dive in, let’s play detective. Identifying the culprits behind your toilet troubles will confirm that your bottom entry fill valve is indeed the problem, and then we can get ready to tackle the repair with confidence.

Signs Your Bottom Entry Fill Valve Needs Replacing

A faulty toilet fill valve is a common plumbing issue, and it can manifest in several annoying ways. If you notice any of these signs, it’s a strong indicator that it’s time to replace bottom entry fill valve in your toilet:

- Toilet Runs Constantly: This is perhaps the most common sign. If your toilet constantly runs, cycling on and off, it means the fill valve isn’t shutting off the water flow completely once the tank is full. This wastes a significant amount of water and can lead to higher utility bills. In fact, a constantly running toilet can waste hundreds of gallons a day. As per the U.S. Department of Energy, a running toilet can waste a significant amount of water.

- Phantom Flushing: Does your toilet seem to flush itself every so often, even when no one has used it? This “phantom flushing” indicates that water is slowly leaking from the tank, causing the fill valve to periodically activate and refill the tank. This is often a symptom of a leaky flapper, but the fill valve is working overtime to compensate.

- Hissing or Gurgling Noises: After a flush, you should hear the tank refill, then silence. If you hear a continuous hiss or gurgle, especially when the tank appears full, it means water is still trying to get past a worn-out fill valve.

- Tank Fills Very Slowly: If it takes an unusually long time for your toilet tank to refill after a flush, the fill valve might be partially blocked, or its internal components are failing, restricting water flow.

- Water Level Too High or Too Low: The fill valve controls the water level in your tank. If the water level is consistently too high (often overflowing into the overflow tube) or too low (leading to a weak flush), the fill valve’s float mechanism might be miscalibrated or broken.

- Leaking Water from the Tank: While leaks can stem from various parts, if you see water dripping from the bottom of the tank, particularly around where the fill valve connects to the water supply line, the fill valve’s seals or connections might be compromised.

- Valve is Over 5 Years Old: As a general rule of thumb, toilet fill valves are recommended to be replaced every 5 years as part of regular toilet maintenance. Even if it’s not showing obvious signs of failure, an aging valve can become less efficient and more prone to issues. Proactive replacement can save you headaches and water down the line.

Choosing the Right Replacement Valve

When it comes time to replace bottom entry fill valve in your toilet, selecting the right replacement is key. Thankfully, most modern fill valves are designed for universal fit and easy installation.

Here’s what to consider:

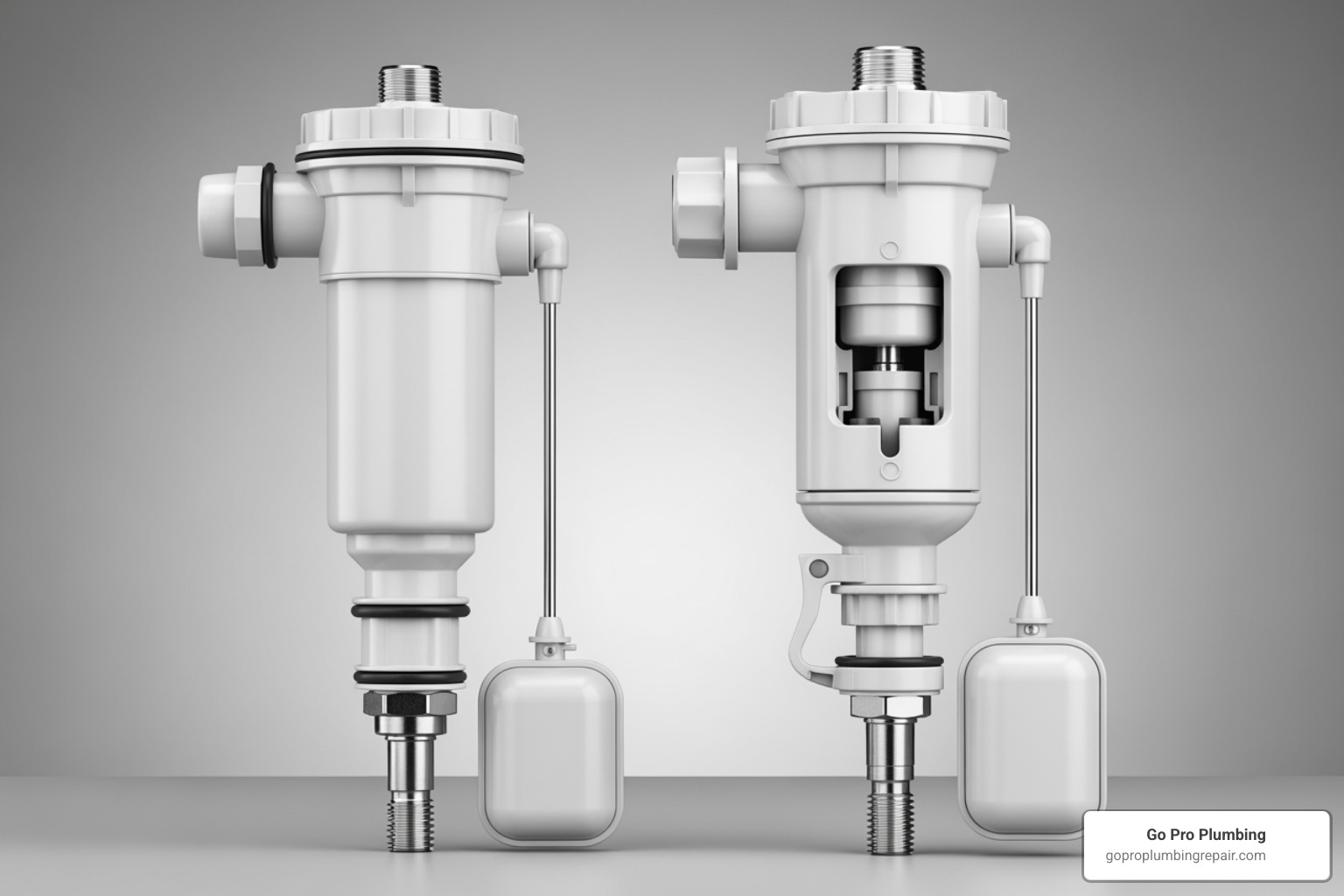

- Bottom Entry vs. Side Entry: This guide specifically focuses on bottom entry fill valves, which connect to the water supply line from the bottom of the toilet tank. These are common in many modern toilets and are generally known for quieter operation because the water fills below the waterline. Side entry valves, on the other hand, connect from the side of the tank and can sometimes be noisier. Ensure you’re replacing a bottom entry with another bottom entry valve unless you’re planning a more complex conversion.

- Universal Fit Valves: Most new fill valves, especially popular brands like Fluidmaster, are designed to be “universal.” This means they fit the majority of 1-piece and 2-piece toilets. Look for packaging that states “universal” or “fits most toilets” to simplify your choice.

- Adjustable Height: A crucial feature for compatibility! Modern fill valves are typically adjustable in height, often ranging from 9 to 14 inches (230mm-355mm). This adjustability ensures the valve fits snugly in your specific toilet tank, regardless of its depth.

- Anti-Siphon Design: This is a non-negotiable safety feature. An anti-siphon design prevents contaminated tank water from flowing back into your home’s fresh water supply, protecting your drinking water. All reputable modern fill valves will include this feature and be code-approved.

- Water Pressure Compatibility: Good quality fill valves are designed to work efficiently with a range of water pressures, whether you have high or low water pressure in your home. This ensures consistent and reliable operation.

| Feature | Bottom Entry Fill Valve | Side Entry Fill Valve |

|---|---|---|

| Water Inlet | Connects from the bottom of the toilet tank | Connects from the side of the toilet tank |

| Noise Level | Generally quieter as water fills below the waterline | Can be noisier, especially older models, due to water splash |

| Aesthetics | Less visible plumbing from the side of the toilet | Water supply line visible from the side |

| Installation | Requires access to the underside of the tank | Easier access to connection point, but can be cramped |

| Cistern Type | Common in many modern toilets, especially in compact designs | Found in many older and some modern toilets |

| Adjustability | Typically height-adjustable to fit various tank depths | Less emphasis on vertical adjustability, more on horizontal clearance |

Tools and Materials You’ll Need

Before we start, let’s gather our supplies. Having everything ready will make the process much smoother and faster, allowing you to replace bottom entry fill valve efficiently.

Here’s a checklist of what you’ll likely need:

- New Bottom Entry Fill Valve Kit: Make sure it’s a universal fit and matches your toilet’s needs.

- Adjustable Wrench: For loosening and tightening the water supply line and the fill valve locknut. Pliers or multi-grips can also work.

- Bucket: To catch any residual water when disconnecting the supply line.

- Old Towels or Rags: For spills and general cleanup.

- Sponge or Wet-Vac: To soak up any remaining water in the tank after flushing.

- Plumbing Tape (Teflon Tape): While not always strictly necessary for modern connections with rubber washers, a few wraps on the threaded connections can provide an extra layer of leak protection.

Step-by-Step Guide to Replace Bottom Entry Fill Valve

Alright, gather your tools, put on your DIY hat, and let’s get that toilet working like new! We’re about to show you how to replace bottom entry fill valve in a few simple steps.

Step 1: Turn Off Water and Drain the Tank

This is the critical first step for any toilet repair involving water.

- Locate the Water Supply Valve: This is typically a small chrome or plastic handle on the wall or floor beneath your toilet tank.

- Shut Off the Water: Turn the handle clockwise until it’s snug. Don’t overtighten, but make sure the water flow stops completely.

- Flush the Toilet: Hold down the flush handle until the tank is as empty as possible. This will remove most of the water.

- Remove Remaining Water: Use your sponge or wet-vac to soak up any lingering water in the bottom of the tank. We want to avoid any unexpected puddles when we disconnect things!

Step 2: How to Remove the Old Bottom Entry Fill Valve

Now that the tank is empty and dry, we can remove the old, problematic valve.

- Prepare for Drips: Place your bucket directly under the water supply line connection beneath the toilet tank. Even with the water off, there might be a few drips.

- Disconnect the Water Supply Line: Using your adjustable wrench, carefully loosen the nut connecting the water supply line to the bottom of the fill valve. Turn it counter-clockwise. Once loose, finish unscrewing by hand.

- Unscrew the Locknut: Still under the tank, locate the large plastic or brass locknut that secures the fill valve to the tank. Use your adjustable wrench or pliers to loosen this nut by turning it counter-clockwise.

- Lift Old Valve Out: Once the locknut is completely removed, you can lift the old fill valve straight up and out of the toilet tank.

- Remove Old Refill Tube: Don’t forget the small refill tube that connects the fill valve to the overflow pipe. Detach this from both the old valve and the overflow pipe.

Step 3: How to Install the New Bottom Entry Fill Valve

With the old valve out, it’s time for the new one to shine! This is where we replace bottom entry fill valve with a fresh, efficient component.

- Prepare the New Valve: Your new fill valve kit will likely include a large rubber washer (shank washer). Slide this onto the threaded shank of the new fill valve, ensuring the flat side is facing up, towards the tank.

- Adjust New Valve Height: Most modern fill valves are height adjustable. Before inserting it into the tank, adjust its height so that the Critical Level (C.L.) Mark (usually a line or “C.L.” printed on the valve) is positioned 1 inch above the top of the overflow pipe. This is important for proper function and code compliance. If your valve doesn’t have a C.L. mark, aim for the top of the fill valve cap to be roughly 3 inches above the top of the overflow pipe, and the water level to sit about 1/2 inch below the top of the overflow pipe. You can often adjust the height by twisting the lower shank or a locking collar.

- Insert New Valve: Lower the new fill valve into the hole at the bottom of the toilet tank. Make sure the nipple (where the refill tube connects) is facing the overflow pipe.

- Hand-Tighten Locknut: From underneath the tank, slide the new locknut onto the threaded shank of the fill valve. Hand-tighten this nut only. Overtightening can crack the tank or the valve stem, leading to leaks and a much bigger headache. It should be snug, but not strained.

- Reconnect Water Supply Line: Reattach the water supply line to the threaded shank of the new fill valve. Again, hand-tighten the coupling nut first, then use your adjustable wrench to give it about a quarter to half a turn until it’s snug. Don’t overtighten! If your water supply connector is old or looks worn (especially if it’s over 5 years old), it’s a good idea to replace it now to prevent future leaks. For more details on toilet maintenance, check out this helpful resource.

Step 4: Final Adjustments and Leak Check

We’re almost there! This step ensures everything is working perfectly and prevents any surprises.

- Turn Water On Slowly: Slowly turn the water supply valve back on (counter-clockwise). Listen for the tank to start filling.

- Check for Leaks: Immediately inspect all connections you’ve touched – the water supply line connection at the valve, the locknut under the tank, and the water supply valve itself. Look for any drips. If you see a leak, turn off the water, gently tighten the connection a little more, and recheck.

- Attach Refill Tube: Connect one end of the small refill tube to the nipple on the new fill valve and the other end to the refill clip. Place the refill clip onto the top of the overflow pipe, ensuring the tube directs water into the overflow pipe, not down into it. Make sure the tube isn’t inserted too far, as this can cause a siphoning effect and make your toilet run constantly.

- Adjust Tank Water Level: Once the tank fills, the fill valve’s float mechanism will shut off the water. The water level in the tank should be about 1/2 inch below the top of the overflow pipe. If it’s too high or too low, adjust the float on the fill valve. Most modern fill valves have an adjustment screw or a sliding collar on the float cup that you can turn or move to raise or lower the water level.

- Adjust Bowl Water Level: Some fill valves have a small dial or roller clamp on the refill tube that allows you to fine-tune how much water flows into the bowl during the refill cycle. This can help ensure a strong flush and a proper bowl water level. Flush the toilet a few times to test the new settings and make any further adjustments.

Post-Installation: Troubleshooting and Pro Tips

Even after a successful replace bottom entry fill valve operation, sometimes little quirks pop up. Here’s how to handle common post-installation issues and some expert advice.

Common Issues After Replacement

Don’t fret if your toilet isn’t perfect right away. These issues are usually easy to fix.

- Fill Valve Won’t Turn On/Off:

- Won’t Turn On: Check if the water supply is fully open. Remove the fill valve cap (twist and lift) and inspect for debris or mineral buildup blocking the inlet. You can flush out debris by holding a cup upside down over the uncapped valve and briefly turning the water on.

- Won’t Turn Off: The float might be sticking or set too high, causing the water level to exceed the shut-off point. Adjust the float to a lower setting. Debris under the valve seal can also prevent it from closing completely.

- Water Level is Too Low/High:

- Too Low: Adjust the float to raise the water level. Ensure the refill tube is properly positioned to direct water into the overflow pipe and not siphoning.

- Too High: Adjust the float to lower the water level. The water should ideally be 1/2 inch below the top of the overflow pipe.

- Leaks from the Base: This usually means a connection isn’t tight enough, or it’s too tight.

- Fill Valve Locknut: If leaking from under the tank, gently tighten the locknut a bit more (remember, hand-tight is best, a small wrench turn if necessary).

- Water Supply Line: If leaking from the supply line connection, check the washer inside the coupling nut and gently tighten. If the supply line is old or worn, replace it.

- Noisy Operation:

- Hissing: Could indicate a partial blockage in the fill valve or a slight leak still occurring.

- Hammering/Vibration: Often related to water pressure issues or a loose connection.

- Flushing Out Debris: If you suspect debris, turn off the water, remove the fill valve cap, and briefly turn the water on to flush out any particles.

- Replacing the Valve Seal: For Fluidmaster valves, if the float cup doesn’t drop when flushing or the valve won’t shut off, the internal seal (e.g., Fluidmaster 242 seal) might need replacing. This can often be done without removing the entire valve.

Special Consideration: Replacing a Valve with Difficult Access

Sometimes, the biggest challenge when you replace bottom entry fill valve isn’t the valve itself, but getting to it! This is particularly true for close-coupled toilets (where the tank is bolted directly to the bowl) or toilets installed very close to a wall.

If you can’t reach the locknut under the tank to disconnect the water supply line and remove the old valve, you might need to:

-

Remove the Toilet Pan: This sounds drastic, but for some toilet designs, it’s the only way to gain proper access. This involves:

- Shutting off the water and draining the tank (as usual).

- Disconnecting the main water supply line.

- Disconnecting the toilet from the waste pipe. Modern toilets often use flexible waste connections, making this easier. Older ones might have a rigid connection that requires more care.

- Unscrewing the bolts that secure the toilet pan to the floor.

- Carefully pulling the entire toilet (tank and bowl) forward. This will give you ample space to work under the tank.

- Once the fill valve is replaced, carefully reverse the steps, ensuring all connections are sealed and the toilet is level before securing it to the floor.

-

When to Consider Professional Help: If the thought of moving your entire toilet pan makes you uncomfortable, or if you encounter rigid waste pipe connections, seized bolts, or persistent leaks, it’s always wise to call in a professional plumber. We at Go Pro Plumbing are experts in toilet repairs and can handle even the trickiest installations in Northern California.

Can I Replace Just the Top Part of the Valve?

Yes, often you can! This is a fantastic time-saving tip, especially for popular brands like Fluidmaster. If you already have a Fluidmaster fill valve and it’s malfunctioning (e.g., constantly running, not filling), the problem might be with the cap assembly or the internal seal.

- Identifying Compatible Valve Models: Many Fluidmaster fill valves, like the 400H or 400UK models, allow for the replacement of just the “business part” – the cap assembly and its internal components, including the seal – without removing the entire unit from the tank. This means you don’t have to disconnect the water supply line or the locknut under the tank.

- Replacing the ‘Business Part’ or Cap Assembly: Typically, you just need to turn off the water, flush the toilet, twist the cap of the fill valve counter-clockwise to remove it, replace the faulty seal or the entire cap assembly, and then twist the new cap back on clockwise. This is a much quicker and less invasive repair! Always check your specific fill valve’s manual or the manufacturer’s website for instructions on this type of repair.

Frequently Asked Questions about Fill Valve Replacement

Here are some quick answers to common questions about how to replace bottom entry fill valve and related issues.

How often should a toilet fill valve be replaced?

We recommend replacing your toilet fill valve about every 5 years as part of regular preventative maintenance. While some might last longer, components can degrade over time, especially in areas with hard water where mineral buildup can occur. Replacing it proactively can prevent unexpected leaks, constant running, and wasted water.

What is the difference between a bottom entry and a side entry fill valve?

The main difference lies in where the water supply line connects to the fill valve on the toilet tank.

- Bottom Entry Fill Valves: The water supply line connects to the bottom of the fill valve, which then passes through a hole in the bottom of the toilet tank. These are generally quieter because the water enters the tank below the water line, reducing splashing noise. They are common in many modern toilet designs.

- Side Entry Fill Valves: The water supply line connects to the side of the fill valve, which typically enters the tank through a hole on the side. These can sometimes be noisier as water might splash more visibly into the tank. They are often found in older toilet models.

Why does my toilet keep running after replacing the fill valve?

If you’ve just performed a replace bottom entry fill valve operation and your toilet is still running, don’t despair! Here are the most common culprits:

- Incorrect Water Level Adjustment: The float on your new fill valve might be set too high, causing the tank to overfill and water to continuously drain into the overflow pipe. Adjust the float to lower the water level to about 1/2 inch below the top of the overflow pipe.

- Flapper or Flush Valve Seal Issue: The fill valve’s job is to stop water from entering. The flapper’s job is to stop water from leaving the tank into the bowl when not flushing. If the flapper is old, worn, or misaligned, water will slowly leak from the tank, causing the fill valve to periodically turn on to refill it (phantom flushing). Check your flapper for wear, proper seating, and make sure its chain has about 1/2 inch of slack. Sometimes, the flush valve seat itself can be corroded.

- Refill Tube Inserted Too Far into Overflow Pipe (Siphoning): The small refill tube should direct water into the overflow pipe, not down into it. If it’s inserted too far below the water line, it can create a siphoning effect, continuously drawing water out of the tank and making the fill valve run to compensate. Trim the refill tube or adjust its clip so it just directs water into the top of the overflow pipe.

Your Toilet is Fixed: What’s Next?

Congratulations! You’ve successfully managed to replace bottom entry fill valve in your toilet. Take a moment to appreciate your DIY prowess and the sweet sound of silence from your newly functioning toilet. Not only have you saved yourself a service call, but you’ve also contributed to water conservation.

Regular plumbing maintenance, like inspecting your toilet for leaks and replacing components every few years, can prevent bigger issues down the road. Keep an eye out for any unusual noises or water levels, and remember that many minor toilet repairs are well within the grasp of a confident homeowner.

However, if you encountered problems during your repair, or if plumbing just isn’t your cup of tea, we’re always here to help. For reliable and efficient plumbing solutions, Go Pro Plumbing offers same-day toilet repair services across Northern California. Whether you’re in Rancho Cordova, Sacramento, or anywhere else in our Northern California service area, our expert plumbers are ready to tackle any plumbing challenge, ensuring your home runs smoothly. Don’t hesitate to give us a call!