Your Guide to Seamless Flexible Gas Riser Setup

By Brian on January 5, 2026

Why Flexible Gas Riser Installation Matters for Your Home

Flexible gas riser installation is the process of connecting underground gas lines to above-ground meters or appliances using specialized pipe assemblies designed to accommodate ground movement. Here’s what you need to know:

Quick Answer: Key Steps for Flexible Gas Riser Installation

- Call 811 before digging to locate underground utilities

- Dig a trench at least 18 inches deep or below your local frost line

- Install tracer wire alongside the buried PE pipe for future location

- Assemble the riser components following manufacturer specifications

- Connect and tighten compression fittings properly to prevent leaks

- Backfill the trench in 6-inch lifts with proper tamping

- Pressure test the system at 25 PSI for at least two hours

- Inspect for leaks using soapy water solution or electronic detection

A flexible gas riser serves as the critical bridge between your underground polyethylene (PE) gas pipe and the above-ground steel piping that connects to your meter. Unlike rigid pipe systems, flexible risers are specifically designed to handle the natural movement of soil caused by frost heave, settling, or ground shifts—common challenges in Northern California.

Why does this matter? Because the transition point where your gas line comes out of the ground is one of the most vulnerable spots in your entire gas system. Without proper installation, ground movement can stress rigid connections, leading to dangerous gas leaks. A properly installed flexible riser moves with the earth, preventing those stress points and ensuring your gas supply remains safe and leak-free for decades.

This guide walks you through every step of the installation process, from planning and safety to testing and final connections.

Understanding the Basics of Flexible Gas Risers

Connecting your home or business to a natural gas supply requires a robust and reliable system. The gas riser is a crucial part of this system, acting as the transition point between the underground gas line and the above-ground meter or appliance. For most residential and commercial applications in areas like Northern California, flexible gas risers are often the best choice due to their unique ability to handle environmental stresses.

What is a Flexible Gas Riser and Why is it Important?

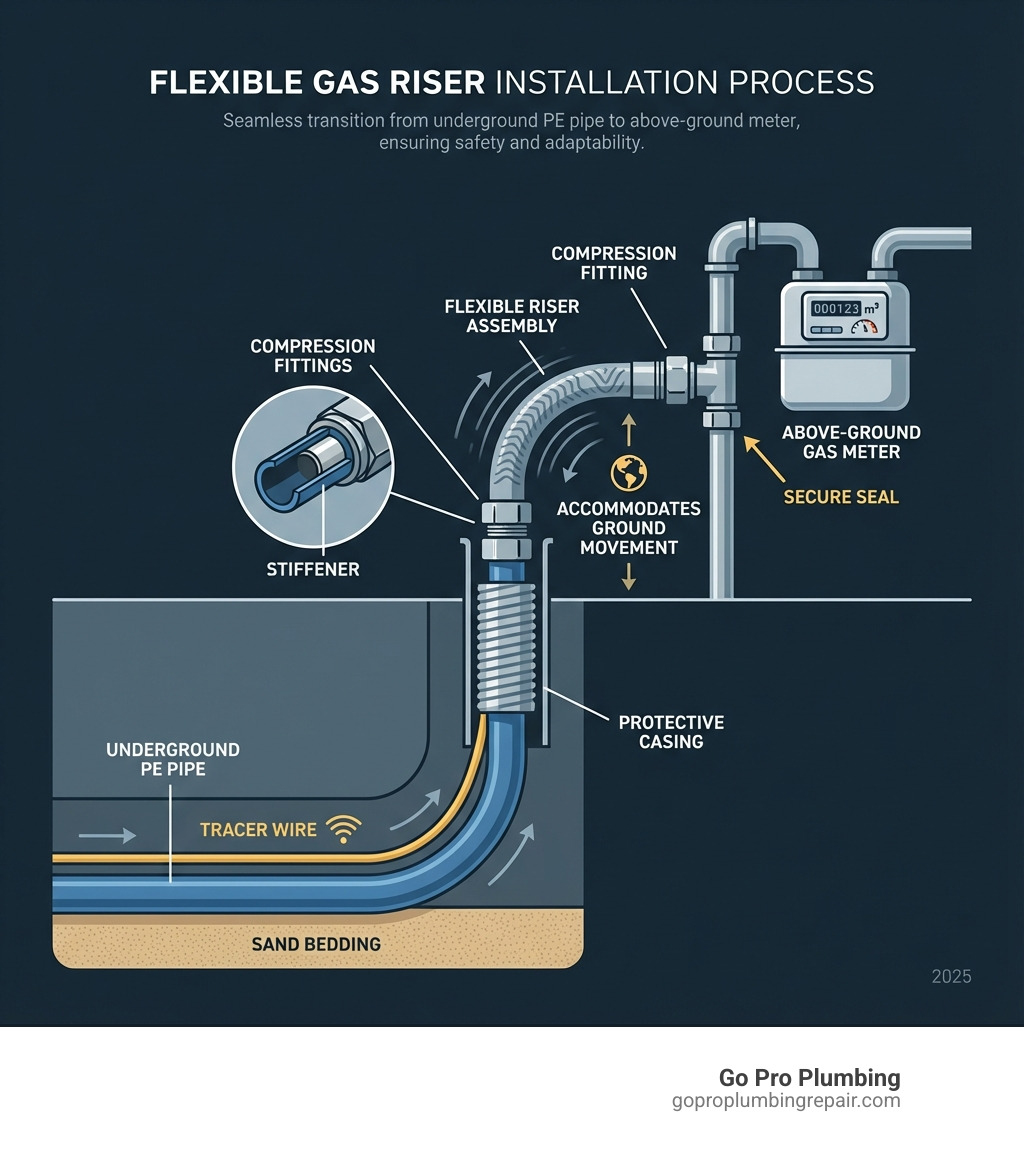

At its core, a flexible gas riser is a specialized pipe assembly designed to safely bring natural gas from an underground polyethylene (PE) main line to an above-ground connection. Its primary function is to serve as a critical bridge, allowing for a safe transition from the flexible underground PE pipe, which is excellent for its corrosion resistance, to the rigid steel piping typically used above ground. The flexible nature of these risers, often encased in a protective steel casing, is key to their importance.

In regions prone to soil movement, like many parts of Northern California, ground shifts due to frost heave, settling, or even minor seismic activity can put immense stress on rigid gas connections. This stress can lead to cracks, leaks, and potentially dangerous situations. Flexible gas risers are specifically engineered to accommodate this movement. By absorbing these forces, they prevent stress from concentrating at the connection points, significantly reducing the risk of leaks and ensuring the longevity and integrity of your gas system. This ability to move with the earth is paramount for safety and continuous, reliable gas service.

Key Components of a Riser System

A flexible gas riser system is a sophisticated assembly of several interconnected parts, each playing a vital role in its overall function and safety. Understanding these components is essential for a successful flexible gas riser installation.

Here are the key components you’ll typically find:

- PE Tubing (Polyethylene Pipe): This is the underground gas line itself, chosen for its excellent corrosion resistance and flexibility. It runs from the main gas supply to the riser.

- Casing/Protective Sleeve: This is often a steel pipe that encases the PE tubing where it transitions from underground to above ground. It provides mechanical protection against physical damage, UV rays, and external stresses.

- Compression Nut: A threaded component that, when tightened, compresses a seal against the PE tubing, creating a secure and leak-tight connection.

- Stiffener/Insert Stiffener: A rigid insert placed inside the end of the PE tubing. It prevents the tubing from collapsing or deforming when the compression nut is tightened, ensuring a consistent internal diameter for gas flow and a reliable seal.

- Gasket/O-ring: These are critical sealing elements made of rubber or other resilient materials. They create a gas-tight seal between the PE tubing and the fitting body when compressed.

- Fitting Body/Adapter Coupling: This is the main metallic component of the riser assembly that connects the PE tubing to the above-ground steel piping, meter, or regulator. It houses the compression mechanism.

- Tracer Wire: A conductive wire run alongside the buried PE pipe. It’s crucial for locating the non-metallic PE pipe underground in the future, preventing accidental damage during excavation. We’ll dig more into this later!

Each of these components must be correctly assembled and installed according to manufacturer specifications to ensure a safe and leak-free gas system.

Common Types of Gas Risers

While our focus is on flexible gas risers, it’s helpful to understand the broader landscape of gas riser types. The choice depends on specific application needs, local codes, and environmental factors. For more general information, you can explore Understanding the Different Types of Risers.

Here’s a brief overview:

- Anodeless Risers: These are a residential standard. They incorporate corrosion protection into their design, eliminating the need for external cathodic protection. They are a common choice for their simplicity and effectiveness in protecting against corrosion.

- Compression Risers: These risers use a mechanical compression fitting to create a seal around the PE pipe. They are often an economical option, but some types may require an anode for additional cathodic protection against corrosion, depending on soil conditions and local requirements.

- Flex Risers: As we’ve discussed, these are designed with built-in flexibility to accommodate ground movement. They are ideal for unstable soil conditions, areas prone to frost heave, or where soil settlement is anticipated. Their design minimizes stress on the gas line, enhancing safety and longevity.

- Rigid Risers: Typically made of steel, rigid risers are robust and used for demanding commercial or industrial sites where ground movement is less of a concern or where specific structural support is provided. They are not typically used in situations where significant ground movement is expected without additional measures.

For most residential and light commercial flexible gas riser installation projects in Northern California, flex risers or anodeless risers are the preferred choices due to their ability to handle ground movement and corrosion resistance.

Pre-Installation: Planning, Safety, and Preparation

Before any digging begins or tools are picked up, meticulous planning, rigorous safety protocols, and thorough preparation are paramount for a successful flexible gas riser installation. Rushing this stage can lead to costly mistakes, dangerous situations, and non-compliance with local regulations. We always emphasize that safety is not just a priority; it’s the foundation of every project we undertake.

Safety First: Essential Precautions

Working with natural gas demands the highest level of caution. Here are the critical safety precautions we always follow:

- Call 811 Before You Dig: This is non-negotiable! At least two business days before any excavation, call 811 (or your local “Dig Safe” equivalent) to have all underground utilities marked. Hitting a gas, water, or electrical line can have catastrophic consequences.

- Shut Off Gas Supply: Before beginning any work on an existing gas line, ensure the main gas supply is completely shut off and verified. Never work on a live gas line.

- Proper Ventilation: If working in an enclosed space, ensure adequate ventilation to prevent gas accumulation, which can be explosive.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, and sturdy footwear.

- Fire Extinguisher: Keep a fire extinguisher rated for gas fires (Class B or ABC) readily accessible.

- No Open Flames or Sparks: Absolutely no smoking, open flames, or spark-producing tools should be used near gas lines.

Improper flexible gas riser installation or application can result in pipe pullout, escaping gas, explosion, property damage, serious injury, or even death. We take these warnings very seriously, and you should too.

Codes, Permits, and Sizing for Your Flexible Gas Riser Installation

Navigating the regulatory landscape is a crucial part of pre-installation.

- Local Building Codes & Utility Specifications: In Sacramento, Rancho Cordova, and across Northern California, specific building codes and utility company requirements govern gas line installations. These dictate approved materials, clearances, installation methods, and testing procedures. We always adhere to these local regulations.

- Pulling Permits & Scheduling Inspections: For any new gas line or significant modification, you will need to pull permits from your local jurisdiction. This ensures that your project is inspected by qualified officials at various stages, verifying compliance with safety standards. Don’t skip this step!

- Sizing the Pipe Correctly: The size of your gas pipe and riser assembly is critical for system performance. It directly affects the amount of gas that can flow to your appliances. Sizing is determined by the total BTU (British Thermal Unit) load of all connected appliances and the total length of the gas pipe run. An undersized pipe can lead to insufficient gas pressure, causing appliances to malfunction or not operate efficiently. We use industry-standard calculations to ensure your gas line can handle your home’s demands.

Tools and Materials Checklist

Having the right tools and materials on hand makes for a smoother and safer flexible gas riser installation. Here’s a basic checklist:

- Pipe Wrenches (2): Often two 24-inch (or larger) pipe wrenches are needed to provide sufficient leverage for tightening compression fittings, especially for larger risers.

- Tubing Cutter: For making clean, square cuts on the PE pipe.

- Chamfering/Deburring Tool: Essential for removing burrs from the inside and outside edges of the cut PE pipe, which can interfere with sealing and proper insertion.

- Clean Cloths: For cleaning pipe ends and components, ensuring no dirt, grease, or oil compromises the seal.

- Approved Thread Sealant: Gas-rated sealant for all threaded metallic connections.

- Leak Detection Solution: A soapy water solution or a specialized electronic gas sniffer for post-installation leak detection.

- Shovel & Digging Tools: For trenching.

- Sand or Fine Soil: For bedding the trench and initial backfill around the pipe.

- Gas Warning Tape: Brightly colored tape to be buried above the gas line as a visual warning for future excavators.

- Pressure Gauge: A 30 PSI gauge for pressure testing the installed line.

- Personal Protective Equipment (PPE): Safety glasses, gloves, etc.

The Critical Steps for Flexible Gas Riser Installation

With planning complete and safety precautions in place, we can now dig into the hands-on process of flexible gas riser installation. This section outlines the typical steps involved, from preparing the ground to connecting the riser components.

Step 1: Trenching and Tracer Wire Placement

The journey of your gas line begins underground.

- Trench Depth: We dig trenches at least 18 inches deep, or deeper if required by local codes to be below the local frost line. This depth protects the pipe from surface damage and temperature fluctuations.

- Sand Bedding: The bottom of the trench is prepared with at least 4 inches of sand or fine soil. This provides a soft, uniform bed for the PE pipe, preventing sharp objects or rocks from damaging it.

- Laying PE Pipe: The polyethylene (PE) pipe is laid in the trench with a gentle slope towards the riser. This helps prevent stress on the pipe.

- Tracer Wire Purpose: Since PE pipe is plastic and cannot be located with standard metal detectors, a tracer wire is absolutely essential. It allows future utility workers or excavators to safely locate the buried gas line using specialized equipment, preventing accidental damage. Think of it as a “breadcrumb trail” for your gas line!

- Tracer Wire Placement: The tracer wire (typically 14 AWG insulated copper wire) is run continuously along the entire length of the buried gas pipe. We place it approximately 6-12 inches above the PE pipe in the trench. It must be continuously connected and accessible at both ends for future testing and locating.

Step 2: Assembling and Connecting the Riser

This is where the magic of the flexible gas riser comes together. The exact steps can vary slightly depending on the specific manufacturer and model of the riser, but the general principles remain consistent. Always follow the manufacturer’s instructions precisely.

- Prepare the PE Tubing:

- Using a tubing cutter, make a clean, square cut on the end of the PE pipe.

- Carefully deburr both the outer (OD) and inner (ID) diameters of the cut pipe. Any burrs can compromise the seal.

- Clean the end of the pipe thoroughly with a clean, dry, grease-free cloth. Do not scratch the pipe surface.

- For some risers, you might need to chamfer the end of the PE tubing to aid insertion.

- Disassemble Components: If necessary, disassemble the compression nut, retainer, gasket, lock ring, and stiffener from the main body of the riser.

- Check Compatibility: Verify that the PE pipe, gasket, and stiffener sizes and SDR (Standard Dimension Ratio) ratings match the riser’s specifications (e.g., ASTM D2513, 1-1/2” IPS, SDR 11, as per some NORMAC instructions). Incompatible parts can lead to leaks or pullout.

- Insert Stiffener: Slide the stiffener completely into the end of the PE pipe until its flange contacts the pipe. This prevents the pipe from deforming under compression.

- Slide Components onto Pipe: Slide the compression nut, retainer, gasket/O-ring, and lock ring onto the PE pipe in the correct sequence, typically with the sealing elements oriented towards the fitting body.

- Install Fitting Body: Thread the fitting body or adapter coupling into the meter outlet, regulator, or other above-ground metallic piping. Use approved gas-rated thread sealant.

- Insert PE Tubing: Carefully insert the PE tubing (with the stiffener and other components) through the riser’s casing and into the fitting body. Ensure the pipe extends the required distance past the end of the swivel nut (e.g., at least 5-6 inches as per some instructions) and reaches the proper stab depth within the fitting body (often indicated by a witness mark, typically within 1/8 inch when fully inserted).

- Tighten the Connection:

- Bring the compression nut up to the fitting body and engage the threads by hand.

- Using two pipe wrenches (holding the fitting body stationary with one and tightening the compression nut with the other), tighten the compression nut. For some risers, this means tightening until it “bottoms against the shoulder” of the adapter coupling, or until it becomes “iron bound” (metal-to-metal contact).

- Crucially, apply sufficient force. For example, some instructions specify applying at least 65 pounds of force to the ends of 24-inch wrenches. Insufficient tightening can lead to leaks or pipe pullout.

- Final Placement: Ensure any red lines or markers on the riser casing are above ground after the final grade, indicating proper installation depth.

Step 3: Accommodating Ground Movement and Backfilling

Once the riser is connected, we turn our attention to protecting it and the underground pipe from future environmental shifts.

- Accommodating Ground Movement: As we’ve emphasized, flexible risers are designed to move with the earth. However, for additional protection, we might also incorporate “swing joints” or other flexible connectors in the above-ground metallic piping near the riser. This prevents rigid anchoring to the foundation, which can create stress points due to frost heave or soil settlement.

- Backfilling in Lifts: We carefully backfill the trench in 6-inch layers or “lifts.” Each layer is lightly compacted to ensure stability and prevent future settlement that could stress the pipe.

- Gas Warning Tape Placement: Approximately 12 inches above the gas pipe, within the backfill, we lay bright yellow gas warning tape. This serves as a vital visual indicator for anyone digging in the area in the future, warning them of the buried gas line.

- Final Grading: The trench is then completely backfilled, and the ground is returned to its original grade.

Post-Installation: Testing and Final Connections

The installation isn’t complete until we’ve confirmed the system’s integrity and made all final connections. This stage is critical for ensuring a leak-free and safe gas supply.

Proper Pressure Testing and Leak Detection

This is arguably the most critical step to guarantee safety.

- Capping the Line: All open ends of the newly installed gas line are capped securely.

- Attaching Pressure Gauge: A pressure gauge (typically a 30 PSI gauge) is attached to the gas line.

- Test Pressure & Duration: We pressure test the capped line to 25 PSI. The system is allowed to stabilize for at least one hour, and then observed for another hour. Any drop in pressure indicates a leak. This rigorous testing ensures the integrity of all connections.

- Leak Detection Methods: Once the pressure test confirms no drop, we perform a meticulous leak detection process. This involves applying a soapy water solution to all joints and connections, looking for bubbles which indicate a leak. Alternatively, we use an electronic gas sniffer, which can detect even minute traces of gas. Every single joint is checked and re-checked.

Connecting to the Meter and Appliances

With a confirmed leak-free system, we can proceed with the final hookups.

- Connecting to Meter Valve: The flexible gas riser is connected to the gas meter’s shut-off valve using approved transition fittings and gas-rated thread sealant.

- Regulator Orientation: If a gas pressure regulator is part of the system, it’s installed in the proper orientation, usually near the meter.

- Individual Appliance Shut-Off Valves: For safety and convenience, individual shut-off valves are installed for each gas appliance (e.g., furnace, water heater, stove). This allows for easy isolation of an appliance without shutting down the entire gas supply.

- Final Inspection: Once all connections are made and the gas supply is restored, we perform a final visual inspection and leak check on all newly made connections. Finally, we schedule any required code and utility inspections to ensure everything meets local standards in Northern California.

Frequently Asked Questions about Flexible Gas Riser Installation

We often get questions about flexible gas riser installation. Here are some of the most common ones:

Why is a tracer wire essential for plastic gas lines?

Tracer wire is absolutely critical for plastic gas lines because polyethylene (PE) pipe is non-metallic. This means it cannot be detected by standard metal detectors used by excavators. Without a tracer wire, locating a buried plastic gas line in the future would be extremely difficult, if not impossible. The tracer wire allows utility workers to use specialized equipment to pinpoint the exact location of the gas line, preventing accidental damage during future digging projects. This is a fundamental safety requirement, as accidentally striking a gas line can lead to dangerous leaks, explosions, and severe injuries. It’s the “breadcrumb trail” that keeps everyone safe!

Can I anchor a gas riser directly to my foundation?

Generally, no, we do not recommend anchoring a gas riser rigidly to your foundation. While it might seem like a secure option, it actually creates stress concentration points. In areas like Northern California, where frost heave, soil settlement, or even minor seismic activity can cause ground movement, a rigidly anchored riser becomes vulnerable. The ground moves, but the foundation and the riser don’t move independently, leading to immense stress on the riser connections. This stress can cause the pipe to crack or pull out, resulting in dangerous gas leaks.

Instead, we recommend using solutions that allow for some flexibility, such as “swing joints” or other flexible connectors in the above-ground piping near the riser. These methods accommodate ground movement, allowing the riser to float slightly with the soil, preventing stress and ensuring the long-term integrity of your gas line.

When Should I Call a Professional for a Flexible Gas Riser Installation?

While this guide provides a comprehensive overview, flexible gas riser installation is a complex and potentially dangerous task that should ideally be handled by experienced professionals. We strongly recommend consulting a professional installer when:

- Code Complexity: Local building codes and utility requirements in Northern California can be intricate and vary by jurisdiction. Professionals are familiar with these codes and ensure full compliance.

- Utility Requirements: Gas companies have specific requirements for how their lines are connected. Professionals understand these nuances.

- Specialized Tools: Proper installation requires specialized tools, such as specific pipe wrenches for tightening to exact specifications, pressure gauges for testing, and leak detection equipment.

- Safety Risks: Working with natural gas carries inherent risks of leaks, fires, and explosions if not handled correctly. The consequences of improper installation are severe.

- When in Doubt: If you have any doubts about your ability to perform any step safely and correctly, it’s always best to call a professional. The peace of mind that comes from a certified, insured, and experienced installer is invaluable.

For residents in Northern California, we at Go Pro Plumbing have certified technicians who understand local codes, utility requirements, and the unique challenges of gas installations in our region. We prioritize your safety and ensure a compliant and reliable installation.

Conclusion: Ensuring a Safe and Successful Installation

A properly executed flexible gas riser installation is a cornerstone of a safe and reliable gas supply for your home or business. We’ve walked through the essential steps, from understanding the components and planning carefully, to the critical phases of trenching, assembly, backfilling, and rigorous testing. The emphasis throughout has been on safety, adherence to local codes in Northern California, and accommodating the natural movement of the earth to ensure long-term reliability.

The flexibility of these risers, the importance of tracer wire, and the absolute necessity of thorough pressure testing and leak detection are not just best practices—they are vital safeguards.

For residents in Northern California, ensuring a safe and compliant installation is paramount. If you have any doubts or need expert assistance, the certified professionals at Go Pro Plumbing are ready to help. Contact us for your gas riser installation needs.